Top 10 Butterfly Valve Suppliers in the USA (2026 Guide)

In the industrial landscape of 2026, the demand for precision flow control ...

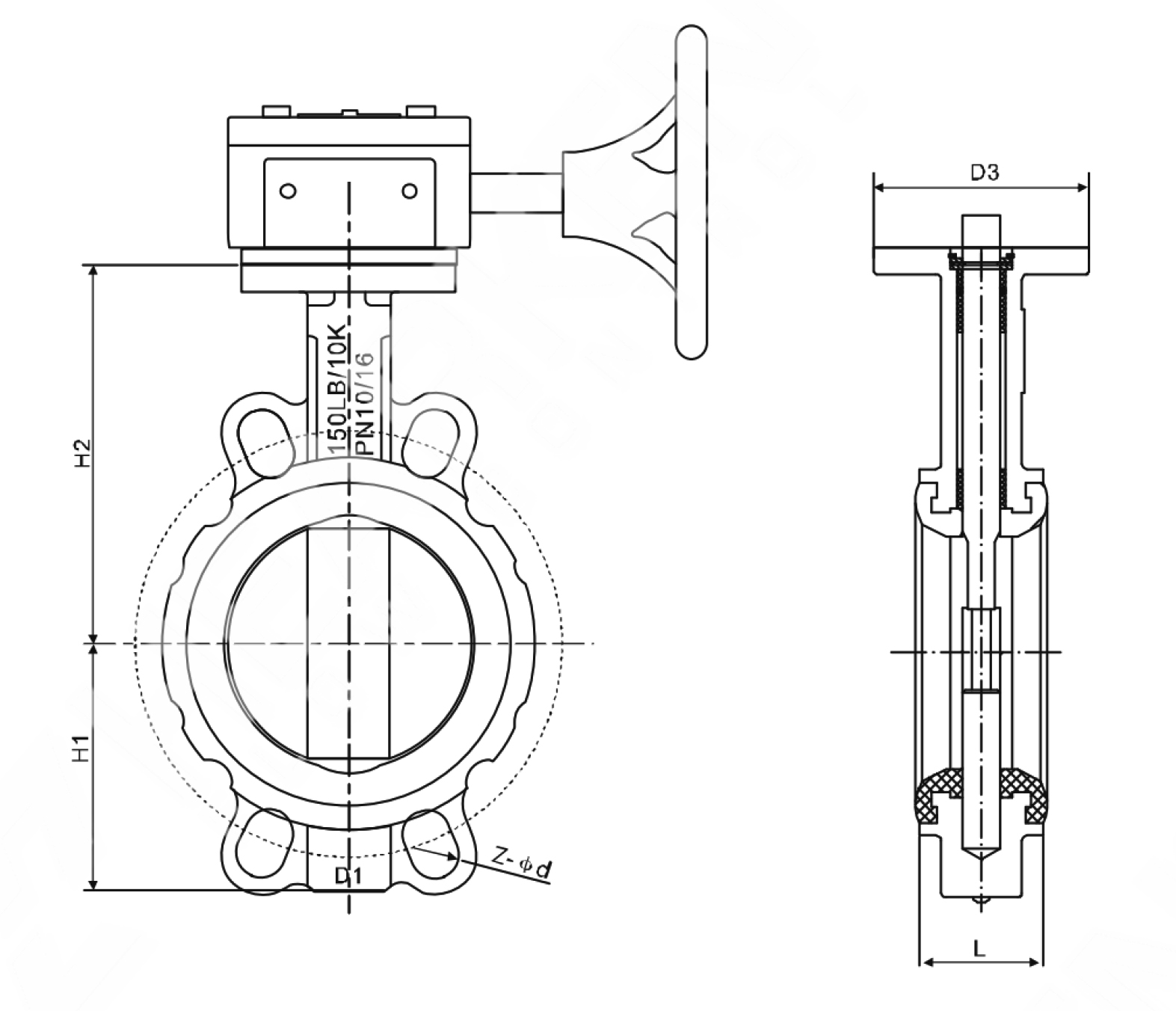

Ductile iron wafer butterfly valve with gearbox is a kind of wafer butterfly valve which is equipped with a gearbox. The valve is made of ductile iron, and it is widely used in water treatment, sewage treatment and other industries. The body of the valve is made of ductile iron, which has excellent physical and mechanical properties, high strength and good ductility. The stem is made of stainless steel, which has excellent corrosion resistance and good wear resistance. The seal is made of EPDM rubber, which has good sealing performance and long service life. The gearbox is made of aluminum alloy, which is light in weight and has good corrosion resistance.

• The design is novel, reasonable, unique structure, light weight and fast.

• Small operation moment, convenient operation and convenient maintenance.

• It can be installed in any position and convenient for maintenance.

• The sealing parts can be replaced, the sealing performance is reliable, and the two - way seal zero leakage.

• The sealing material is resistant to aging, corrosion resistance and long service life.

• The structure is simple, the universal interchange is good and the price is low.

• Stem seal is not easy to deform to avoid the usual stem leakage.The overall support is good, stable and firm.

• Seat rubber consumption, expand the potential impact of small, easy to control the torque values within the scope of the appropriate USES two pieces type stem connection without pin, simple and compact structure, convenient in maintenance disassembly.

• The butterfly board has automatic alignment function, and the butterfly plate and seat small oversize fit. Phenolic back seat has the characteristics of non-shedding, tensile, leakproof and convenient replacement, Because seat airtight cover is integral to backrest, the seating deformation is reduced.

Design Standard:GB/T12238-2008、GB/T3036-94、S010631-1994 or BS EN593-2004、BS5155、MSSSP-67、AP1609 GOST-12815、CNSI2744、MSSSP-67-2002、GB/T3036-94、AWWAC504-2000GB/T17241.6-2008、JIS B2212-B2214-1999、DIN 2501、JIS B2220-2004、JIS 2210-1984、BS 4504

Flange Connection:BS10-E、ANS-16.5-2009、ANSI B 16.47-2006、AS2129、ANSI 1259、SO7005-2 o r BS EN1092-2002 Gb9112、 IS02084、 ISO2531 GOST12820-80、 HG/T20623/20615/20592(PN6、 PN10、 PN16 Class125、Class150、5K、10K、16K)

Structural length: GB/T12221-2005、JIS B2032-2013、ISO5752-1988 or BS EN558-1

Pressure Test: GB/T13927-2008、JB/T9092-1999、S0528-1993 or BS 5755-1-1986、 AP1598-2004、 EN12266-1.JB/T3595-93

Top flange: ISO5211

| Part | Material | ASTM |

| Body | Cast lron Ductile lron |

A126 Class B A536 65-45-12 |

| Disc | Ductile Iron Bronze Stainless Steel 304 Stainless Steel 316 |

A536 65-45-12 B148 C95400 A351 CF-8 A351 CF-8M |

| Shaft | Stainless Steel 316 Stainless Steel 410 Stainless Steel 431 |

A276 S316 00 A276 S 410 00 A276S 431 00 |

| Seat Ring | EPDM/NBR/VITON/PTFE | Soft/backrest/vulcanized |

| Taper Pins | Stainless Steel 304 Stainless Steel 316 Stainless Steel 410 |

A276 S 304 00 A276 S 316 00 A276 S410 00 |

| Key | Carbon Steel | |

| O-Ring | EPDM/NBR | |

| Bushing | PTFE Bronze |

B62 C83600 |

| DN (mm) |

L | D | PN1.0 | PN1.6 | 150Lb | 10K | D3 | H1 | H2 | ||||

| D1 | Z-φd | D1 | Z-φd | D1 | Z-φd | D1 | Z-φd | Flange No. | |||||

| 50 | 42 | 52.9 | 125 | 4-19 | 125 | 4-23 | 120.6 | 4-19 | 120 | 4-19 | F05 | 73 | 125 |

| 65 | 44.7 | 64.5 | 145 | 4-19 | 145 | 4-23 | 139.7 | 4-19 | 140 | 4-19 | F05 | 82 | 136 |

| 80 | 45.2 | 78.8 | 160 | 8-19 | 160 | 8-20 | 152.4 | 4-19 | 150 | 8-19 | F05 | 91 | 142 |

| 100 | 52.1 | 104 | 180 | 8-19 | 180 | 8-23 | 190.5 | 8-19 | 175 | 8-19 | F07 | 104 | 163 |

| 125 | 54.4 | 123.3 | 210 | 8-19 | 210 | 8-23 | 215.9 | 8-22 | 210 | 8-23 | F07 | 127 | 176 |

| 150 | 55.8 | 155.6 | 240 | 8-23 | 240 | 8-25 | 241.3 | 8-22 | 240 | 8-23 | F07 | 138 | 197 |

| 200 | 60.6 | 202.5 | 295 | 8-23 | 295 | 12-25 | 298.5 | 8-22 | 290 | 12-23 | F10 | 170 | 230 |

| 250 | 65.6 | 250.5 | 350 | 12-23 | 355 | 12-28 | 362 | 12-25 | 355 | 12-25 | F10 | 204 | 261 |

| 300 | 77 | 301.6 | 400 | 12-23 | 410 | 12-28 | 432 | 12-25 | 400 | 16-25 | F10/F12 | 241 | 294 |

| 350 | 76.5 | 333.3 | 460 | 16-23 | 470 | 16-30 | 476 | 12-29 | 445 | 16-25 | F10/F12 | 263 | 335 |

| 400 | 86.5 | 389.6 | 515 | 16-28 | 525 | 16-30 | 540 | 16-29 | 510 | 16-27 | F14/F16 | 309 | 400 |

| 450 | 105.6 | 440.5 | 565 | 20-28 | 585 | 20-30 | 578 | 16-32 | 565 | 20-27 | F14/F16 | 328 | 420 |

| 500 | 132 | 491.6 | 620 | 20-28 | 650 | 20-33 | 635 | 20-32 | 620 | 20-27 | F14/F16 | 361 | 480 |

| 600 | 152 | 592.5 | 725 | 20-31 | 770 | 20-36 | 749.5 | 20-35 | 730 | 24-32 | F25 | 459 | 560 |

| 700 | 163 | 695 | 840 | 24-31 | 840 | 24-36 | 864 | 28-35 | 840 | 24-33 | F25 | 520 | 624 |

| 800 | 188 | 794.7 | 950 | 24-34 | 950 | 24-39 | 978 | 28-41 | 950 | 28-33 | F25 | 590 | 680 |

| 900 | 203 | 864.7 | 1050 | 28-34 | 1050 | 28-39 | 1086 | 32-41 | 1050 | 28-33 | F25 | 656 | 720 |

| 1000 | 216 | 965 | 1160 | 28-37 | 1170 | 28-42 | 1200 | 36-41 | 1160 | 28-39 | F25 | 720 | 800 |

| 1200 | 276 | 1158 | 1380 | 32-40 | 1390 | 28-49 | 1422 | 44-41 | 1380 | 32-39 | F30 | 844 | 941 |

2026

/

In the industrial landscape of 2026, the demand for precision flow control ...

2026

/

Efficiency is the top priority in any modern piping system. You need compon...

2026

/

Choosing the correct pneumatic actuator is essential for industrial automat...

2026

/

A valve limit switch box is a key part of your automation setup. It serves ...

GET A QUOTE