How to Select the Pneumatic Actuator?

Choosing the correct pneumatic actuator is essential for industrial automation. A well-selected actuator improves machine life and reduces energy costs. This guide will walk you through the professional selection process step-by-step.

Define Your Application Requirements

Before buying hardware, you must understand the work the actuator will perform.

Motion and Direction

First, decide on the motion type. Linear actuators move loads in a straight line (push or pull). Rotary actuators turn objects, such as opening a ball valve.

Force and Stroke Length

Calculate the force needed for both extension and retraction. Use this formula for a basic estimate:

F = P* A

Where F is force, P is air pressure, and A is the piston area. Always add a safety factor of 25% to 50%. This accounts for friction and air pressure drops in your factory. Finally, measure the stroke length, which is the exact distance the load needs to move.

Select the Actuator Type

Different designs solve different mechanical problems.

Linear Actuator Varieties

- Single-Acting Cylinders: These use air to move in one direction and a spring to return. They are perfect for simple clamping or fail-safe tasks.

- Double-Acting Cylinders: These use air for both directions. They offer better control and are the most popular choice in automation.

- Rodless Actuators: These are ideal for long strokes. Since the "piston" moves inside the body, they save a lot of space.

Rotary Actuator Varieties

- Vane Type Actuator: Very compact. Use these for simple 90 or 180-degree turns.

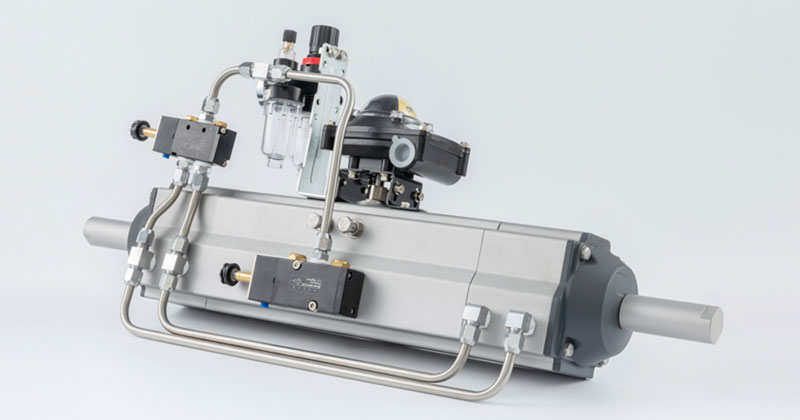

- Rack and Pinion Actuator: These provide high torque and constant speed. They are great for heavy-duty industrial valves.

Environmental and Material Considerations

The environment determines how long your actuator will last.

- Temperature: Standard seals work up to 80°C. If your machine is near a furnace, you need high-temperature Viton seals.

- Corrosion: Standard aluminum is light and cheap. However, use Stainless Steel for food grade or chemical environments.

- Ingress Protection: In dusty or wet areas, check the IP rating. Some environments might even require ATEX-certified actuators for explosive safety.

Integration, Control, and Hearken Solutions

Modern systems require precision. This is where high-quality components make a difference.

Feedback and Mounting

To tell your PLC where the piston is, use magnetic reed switches or solid-state sensors. You also need to choose a mounting style, such as foot mounts, flanges, or clevises.

Why Choose Hearken Pneumatic Actuators?

When reliability is non-negotiable, Hearken provides industry-leading solutions. Hearken pneumatic actuators are designed with precision-honed internal surfaces to reduce friction.

Whether you need the Hearken ISO 15552 Standard Series for general automation or the Hearken Compact Series for tight spaces, these products prioritize durability. Hearken actuators often feature adjustable air cushioning. This protects your machine from heavy impacts, reducing noise and maintenance costs.

Maintenance and Total Cost of Ownership (TCO)

Don't just look at the price tag. Think about long-term costs.

- Standardization: Hearken follows international standards like ISO and NFPA. This means you can find replacement parts easily anywhere in the world.

- Energy Efficiency: An oversized actuator wastes expensive compressed air. Use Hearken’s sizing tools to pick the exact size you need.

- Repairability: High-quality actuators from Hearken allow you to replace seals rather than throwing the whole unit away.

FAQ

Q1. What is the difference between single-acting and double-acting actuators?

Single-acting uses air for one direction and a spring for the other. Double-acting uses compressed air for both extension and retraction, providing more power and control.

Q2. How do I prevent my actuator from slamming at the end of its stroke?

You should use adjustable air cushioning. Most Hearken actuators include this feature to slow the piston down just before it hits the end-cap.

Q3. When should I use a rodless pneumatic actuator?

Use a rodless actuator when you have a very long stroke (over 1 meter) but limited space. They are much shorter than standard cylinders when fully extended.

Q4. Can I use standard actuators in a food processing plant?

Usually, no. You should use stainless steel actuators to prevent rust and handle harsh cleaning chemicals.

Q5. How much air pressure do I need?

Most industrial pneumatic systems operate between 0.5 to 0.7 MPa (5 to 7 Bar). Always check your actuator’s minimum operating pressure before installation.