How to Choose the Best 3-Way Pneumatic Ball Valve?

In today's industrial automation systems, reliable flow control is critical for operational efficiency. The 3-piece pneumatic actuated ball valve stands out as a premier solution for fluid management with its compact design and exceptional performance.

But with so many options available, how do you select the right one for your application? HEARKEN's stainless steel pneumatic ball valves combine precision engineering with rugged durability to deliver unmatched reliability.

Why Choose a 3-Piece Pneumatic Ball Valve?

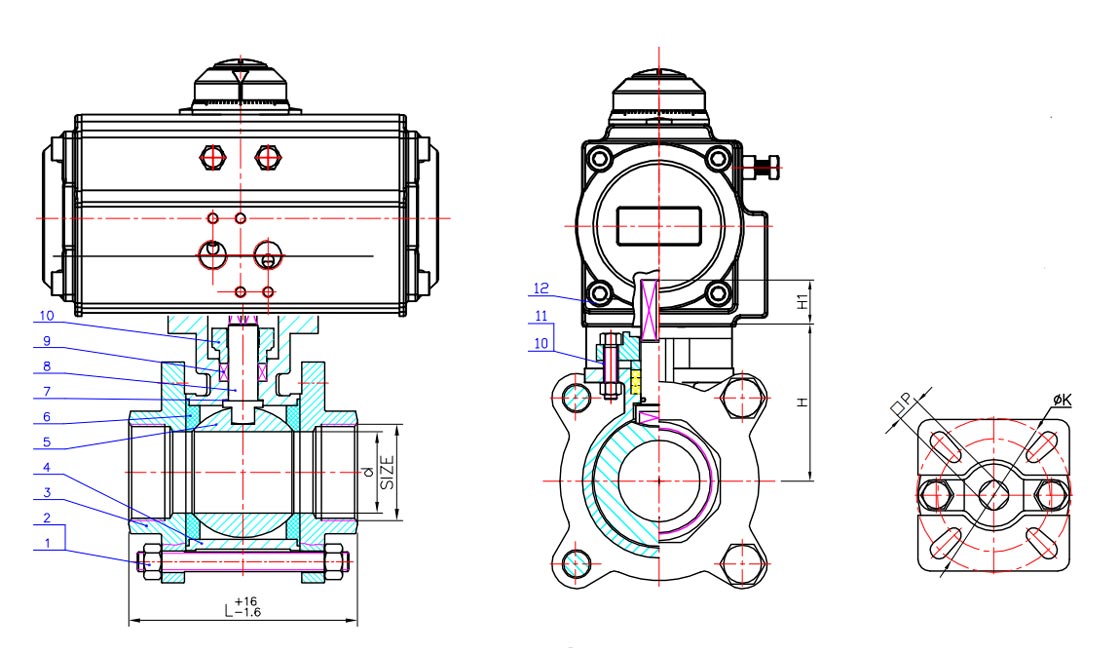

Pneumatic ball valves consist of two key components: the pneumatic actuator and valve body. HEARKEN's 3-piece design offers distinct advantages over conventional valves:

Key Benefits:

- Modular Construction - Easy maintenance with ISO standard flange connections

- Superior Sealing - Polished ball and seats prevent media contamination

- Flexible Actuation - Choose between single-acting (spring return) or double-acting models

- Corrosion Resistance - 304/316 stainless steel construction

- Cost Effective - Lower investment vs electric valves for large diameters

Top Industry Applications:

Water Treatment Plants - Precise flow control in filtration systems

Chemical Processing - Reliable performance with aggressive media

Food & Beverage - Sanitary design meets hygiene stan

Pharmaceutical - Clean-in-place compatible solutions

Oil & Gas - Robust performance in demanding environments

Why HEARKEN Stands Out:

- 30+ Years Manufacturing Expertise

- Complete Quality Certifications (ISO 9001, CE)

- Global Technical Support Network

- Custom Engineering Solutions Available

Ready to upgrade your flow control system? Contact HEARKEN engineers today for a free consultation!