How to Select the Right Pneumatic Angle Seat Valve: A Comprehensive Buyer’s Guide

Choosing a pneumatic angle seat valve shouldn't feel like a guessing game. ...

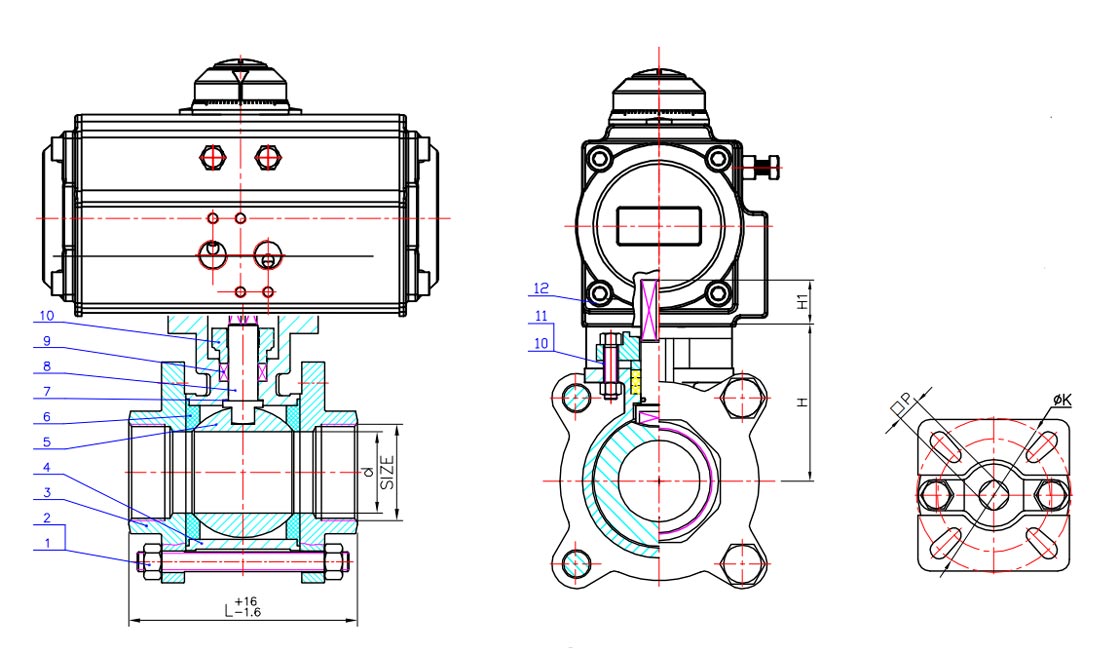

A pneumatic actuated ball valve can be broken down into two main components. The pneumatic actuator and the ball valve. For a 2-way ball valve, the pneumatic actuator can turn the ball 90 degrees to be either fully open or fully closed. For a 3-way valve, the pneumatic actuator can turn the ball between different circuits depending if it is an L-port or T-port ball valve. They are mounted together typically with a standard flange adhereing to ISO 5211. This allows both the pneumatic actuator or ball valve to be swapped out with another one using the same flange size.

A pneumatic actuator requires compressed air to operate. The actuator can either be single or double acting. A single acting pneumatic actuator uses compressed air to rotate the ball in one direction and uses a spring to move it back to the normal position. A double acting pneumatic actuator requires compressed air to move the ball in either direction. An air actuated ball valve is a reliable solution and often a lower investment cost for larger valves compared to an electric ball valve. There are various housings and sizes of pneumatic ball valves to allow you to find the right one for your application. Air operated ball valves are commonely used for remote control of a flow, like a water pipe or air hose.

1.Design andmanufacture as per API 608.

2.End to end dimension be established by the manufacturer.

3.Thread end dimension as per ASME B1.20.1.

4.Test & inspection as per API 598.

| Main Technical Parameter | |||

| Normal Pressure | 1000 | Psi | |

| Test Pressure | Shell test pressure | 10.5 | |

| Tightmess test | 7.7 | Mpa | |

| Gas-Tightness test | 0.6 | ||

| Max working temperature | -20~150 | °C | |

| Applicable medium:water,gas,oil,acid | |||

| No. | Part Name | Material |

| 1 | Bolt | B8M-CL2 |

| 2 | Nut | 8M |

| 3 | End Connector | CF8/CF8M |

| 4 | Body | CF8/CF8M |

| 5 | Ball | 304 |

| 6 | Sealing Ring | PTFE/RPTFE/PPL |

| 7 | Gasket | PTFE |

| 8 | Stem | 304 |

| 9 | Stem Packing | PTFE/RPTFE/PPL |

| 10 | Gland | VF8 |

| 11 | Bolt | B8M |

| 12 | Nut | 8M |

| 13 | Actuator | Aluminium Alloy |

| DN | Size | d | L | ΦK | □ P | H | H1 | Torque N.m |

| 15 | 1/2" | 15 | 67 | 50 | 9 | 50 | 10 | 6 |

| 20 | 3/4" | 20 | 78 | 50 | 9 | 55 | 10 | 8 |

| 25 | 1" | 25 | 87 | 50 | 11 | 55 | 12 | 10 |

| 32 | 1 1/4" | 32 | 100 | 50 | 11 | 67 | 12 | 12 |

| 40 | 1 1/2" | 38 | 110 | 70 | 14 | 78 | 15 | 20 |

| 50 | 2" | 49 | 130 | 70 | 14 | 83 | 15 | 28 |

| 65 | 2 1/2" | 65 | 167 | 102 | 17 | 115 | 18 | 33 |

| 80 | 2 1/2" | 78 | 200 | 102 | 17 | 130 | 18 | 51 |

| 100 | 4“ | 100 | 240 | 102 | 19 | 150 | 20 | 66 |

2026

/

Choosing a pneumatic angle seat valve shouldn't feel like a guessing game. ...

2026

/

With 15 years of expertise in manufacturing and global trade, Hearken deliv...

2026

/

In 2026, the U.S. solenoid valve market is defined by Smart Manufacturing a...

2026

/

Choosing the right valve is vital for system efficiency. A wrong choice can...

GET A QUOTE