How to Select the Right Pneumatic Angle Seat Valve: A Comprehensive Buyer’s Guide

Choosing a pneumatic angle seat valve shouldn't feel like a guessing game. ...

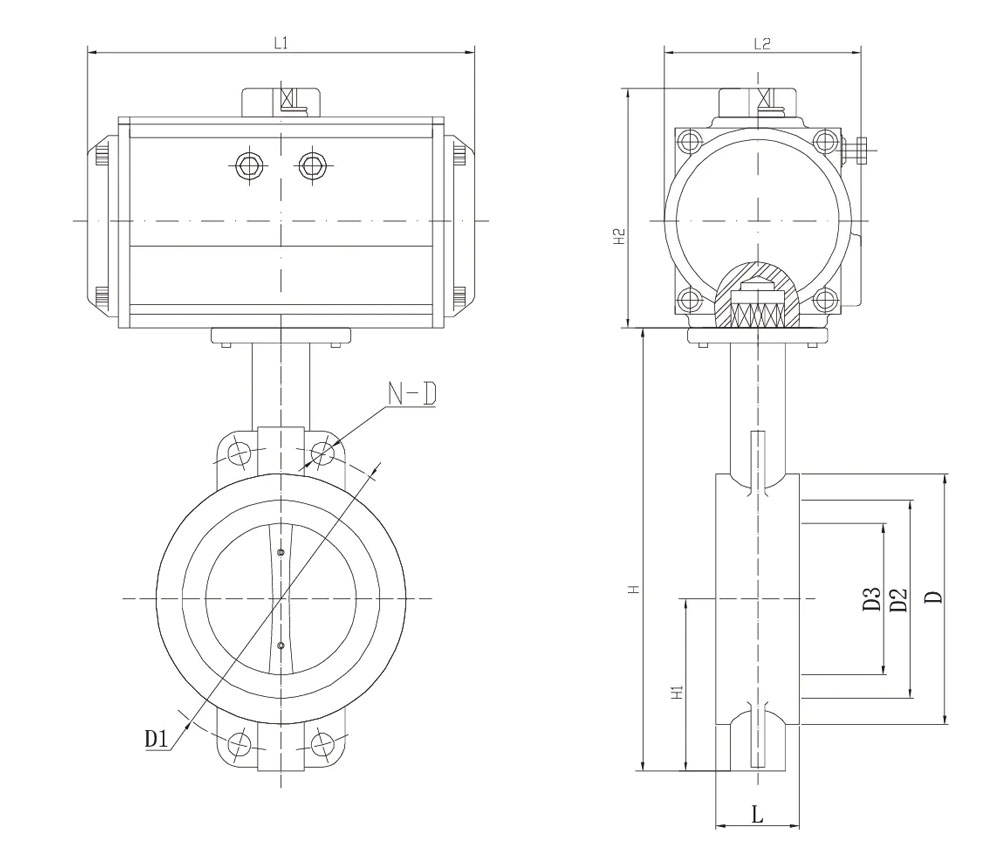

Cast Iron pneumatic butterfly valve is composed of pneumatic actuator and butterfly valve. Pneumatic butterfly valve is a pneumatic valve that uses a circular butterfly plate that rotates with the valve stem to open and close to realize the activation action. It is mainly used as a shut-off valve, and can also be designed to have the function of adjusting or shutting and adjusting.

Pneumatic actuated center line butterfly valve is a type of valve that uses compressed air to open and close a disk-shaped valve in a fluid flow line. The pneumatic actuated valve is typically used to regulate the flow of liquids and gases. The pneumatic actuated valve is operated using an actuator, which is a pneumatically powered device that is activated by a controller. The controller can be mechanical or electronic, depending on the specific needs of the application. Pneumatic actuated valve can be opened and closed manually or automatically, depending on the requirements of the system. The center line butterfly valve is generally used in applications where a tight shutoff is required or when bi-directional flow needs to be regulated.

• The design is novel, reasonable, unique structure, light weight and fast.

• Small operation moment, convenient operation and convenient maintenance.

• It can be installed in any position and convenient for maintenance.

• The sealing parts can be replaced, the sealing performance is reliable, and the two - way seal zero leakage.

• The sealing material is resistant to aging, corrosion resistance and long service life.

• The structure is simple, the universal interchange is good and the price is low.

• Stem seal is not easy to deform to avoid the usual stem leakage.The overall support is good, stable and firm.

• Seat rubber consumption, expand the potential impact of small, easy to control the torque values within the scope of the appropriate USES two pieces type stem connection without pin, simple and compact structure, convenient in maintenance disassembly.

• The butterfly board has automatic alignment function, and the butterfly plate and seat small oversize fit. Phenolic back seat has the characteristics of non-shedding, tensile, leakproof and convenient replacement, Because seat airtight cover is integral to backrest, the seating deformation is reduced.

Design Standard:GB/T12238-2008、GB/T3036-94、S010631-1994 or BS EN593-2004、BS5155、MSSSP-67、AP1609 GOST-12815、CNSI2744、MSSSP-67-2002、GB/T3036-94、AWWAC504-2000GB/T17241.6-2008、JIS B2212-B2214-1999、DIN 2501、JIS B2220-2004、JIS 2210-1984、BS 4504

Flange Connection:BS10-E、ANS-16.5-2009、ANSI B 16.47-2006、AS2129、ANSI 1259、SO7005-2 o r BS EN1092-2002 Gb9112、 IS02084、 ISO2531 GOST12820-80、 HG/T20623/20615/20592(PN6、 PN10、 PN16Class125、Class150、5K、10K、16K)

Structural length: GB/T12221-2005、JIS B2032-2013、ISO5752-1988 or BS EN558-1

Pressure Test: GB/T13927-2008、JB/T9092-1999、S0528-1993 or BS 5755-1-1986、 AP1598-2004、 EN12266-1.JB/T3595-93

Top flange: ISO5211

|

Operated Type |

Pneumatic Actuator Wafer Type Butterfly Valve * ISO5211 Mount |

|

Size |

DN50 to DN1200 |

|

Body Material |

Epoxy Coated Cast, Ductile Iron, SS304/SS316, WCB, Aluminium Alloy, |

|

Disc Material: |

SS304/SS316, Aluminum Bronze, Nylon, Ductile iron |

|

Seal Material and Work Temperature |

EPDM: -15~85°C PTFE: -25~150°C NBR: -15~85°C VITON: -25~200°C |

|

Connection Standard |

PN10/PN16, ANSI150, DIN16, JIS10K/16K |

|

Pressure Rating |

PN6 / PN10 / PN16 |

|

Medium |

Water, Oil, Gas, Powder |

|

Actuator Model |

HPA Series On off Quarter Turn Pneumatic Actuator |

|

Model |

Wafer Butterfly Valve Size |

Torque @ 4Bar |

Torque @ 5Bar |

Square |

Depth |

Flange Size |

Operating Time(s) |

Adapter Size |

DA Weight (Kgs) |

SR Weight (Kgs) |

||

|

DA |

SR |

DA |

SR |

|||||||||

|

HPA052 |

DN50 |

16.1 |

7.2 |

20.2 |

11.3 |

11*11 |

14 |

F03/F05 |

0.5 |

11-9 |

1.4 |

1.5 |

|

HPA063 |

DN65 |

28.4 |

14 |

35.5 |

21.1 |

14*14 |

18 |

F05/F07 |

0.5 |

14-11-9 |

2 |

2.1 |

|

HPA075 |

DN80 |

40.3 |

18.1 |

50.3 |

28.1 |

14*14 |

18 |

F05/F07 |

1.5 |

14-11-9 |

2.7 |

2.9 |

|

HPA083 |

DN100 |

61.6 |

28.3 |

77.1 |

43.8 |

17*17 |

21 |

F05/F07 |

1.5 |

17-14-11 |

3.1 |

3.6 |

|

HPA092 |

DN125 |

90.9 |

41 |

113.6 |

64 |

17*17 |

21 |

F05/F07 |

2 |

17-14 |

4.6 |

5.2 |

|

HPA105 |

DN150 |

131.6 |

65 |

164.4 |

97 |

22*22 |

26 |

F07/F10 |

2 |

22-17-14 |

6.8 |

6.9 |

|

HPA125 |

DN200 |

205 |

94 |

256 |

145 |

22*22 |

26 |

F07/F10 |

2.5 |

22-17-14 |

8.9 |

10.1 |

|

HPA140 |

DN250 |

351 |

170 |

439 |

258 |

27*27 |

31 |

F10/F12 |

4 |

27-22 |

13 |

15 |

|

HPA160 |

DN300 |

535 |

241 |

668 |

374 |

27*27 |

31 |

F10/F12 |

5 |

27-22 |

20 |

24 |

|

HPA190 |

DN350 |

861 |

440 |

1077 |

656 |

36*36 |

40 |

F14 |

5 |

36-27 |

31 |

35 |

|

HPA210 |

DN400 |

1052 |

473 |

1316 |

737 |

36*36 |

40 |

F14 |

7 |

36-27 |

47 |

55 |

|

HPA240 |

DN450 |

1546 |

682 |

1933 |

1069 |

46*46 |

50 |

F16 |

10 |

46-36 |

67 |

80 |

|

HPA270 |

DN500 |

2349 |

1171 |

2936 |

1758 |

46*46 |

50 |

F16 |

10 |

46-36 |

97 |

118 |

|

HPA300 |

DN600 |

3052 |

1430 |

3815 |

2193 |

46*46 |

50 |

F16 |

|

46-36 |

110 |

130 |

|

HPA350 |

DN700 |

4570 |

1963 |

5712 |

3105 |

46*46 |

50 |

F16/F25 |

|

46-36 |

186 |

234 |

|

HPA400 |

DN800 |

6511 |

3595 |

8139 |

5223 |

46*46 |

50 |

F16/F25 |

|

46-36 |

289 |

360 |

|

No. |

Part Name |

Material |

|

|

1 |

Valve Seat |

Rubber/NBR/EPDM/PTFE |

|

|

2 |

Valve Disc |

Carbon Steel/Stainless Steel |

|

|

3 |

Valve Body |

Cast Iron/Carbon Steel/Stainless Steel |

|

|

4 |

Valve Stem |

45# Steel/2Cr13/Stainless Steel |

|

|

5 |

Sealing |

Rubber/Viton/PTFE |

|

|

6 |

Bushing |

PTFE Composite Bearings |

|

|

7 |

Stem Position Ring |

PTFE/PEEK/Stainless Steel |

|

|

8 |

Circlip |

Stainless Steel |

|

|

9 |

Solenoid Valve |

Aluminum Alloy |

|

|

10 |

Pneumatic Actuator |

Aluminum Alloy |

|

|

11 |

Air Filter |

Aluminum Alloy + Polycarbonate |

|

|

12 |

Limit Switch Box |

Aluminum Alloy |

|

DN |

IN |

L |

H |

H1 |

L1 |

L2 |

H2 |

D |

D1 |

D2 |

N-D |

Actuator Model |

|

40 |

1 1/2" |

33 |

147 |

53 |

153.7/188.3 |

72.5/95.5 |

92.3/121 |

80 |

110 |

68 |

4-16 |

HPA052DA/HPA075SR |

|

50 |

2" |

42 |

195 |

55 |

153.7/188.3 |

72.5/95.5 |

92.3/121 |

95 |

125 |

82 |

4-16 |

HPA052DA/HPA075SR |

|

65 |

2 1/2" |

44 |

217 |

64 |

172.4/215 |

83/103.5 |

110.7/128 |

114 |

145 |

97 |

8-16 |

HPA063DA/HPA083SR |

|

80 |

3" |

44 |

232 |

73 |

188.3/248.5 |

95.5/108 |

120/136.2 |

126 |

160 |

113 |

8-16 |

HPA075DA/HPA092SR |

|

100 |

4" |

50 |

270 |

88 |

215/248.5 |

103.5/108 |

121/136.2 |

154 |

180 |

139 |

8-16 |

HPA083DA/HPA092SR |

|

125 |

5" |

56 |

292 |

102 |

248.5/277.5 |

108/121.5 |

136.2/154.5 |

180 |

210 |

163 |

8-16 |

HPA092DA/HPA105SR |

|

150 |

6" |

56 |

318 |

115 |

277.5/358.3 |

121.5/142 |

154.5/187.6 |

206 |

240 |

195 |

8-20 |

HPA105DA/HPA125SR |

|

200 |

8" |

60 |

390 |

149 |

358.3/403.6 |

142/151 |

187.6/204.7 |

264 |

295 |

250 |

8-20/12-20 |

HPA125DA/HPA140SR |

|

250 |

10" |

68 |

457 |

184 |

403.6/468.4 |

151/174 |

204.7/230 |

320 |

350/355 |

305 |

12-20/12-24 |

HPA140DA/HPA160SR |

|

300 |

12" |

78 |

518 |

207 |

468.4/523.5 |

174/206 |

230/262 |

370 |

400/410 |

352 |

12-20/12-24 |

HPA160DA/HPA190SR |

|

350 |

14" |

78 |

610 |

247 |

523.5/539 |

206/226 |

262/287.6 |

430 |

460/470 |

405 |

16-20/16-24 |

HPA190DA/HPA210SR |

|

400 |

16" |

102 |

650 |

275 |

539/605.8 |

226/260 |

287.6/319.5 |

480 |

515/525 |

455 |

16-24/16-27 |

HPA210DA/HPA240SR |

|

450 |

18" |

114 |

713 |

307 |

605.8/719 |

260/294 |

319.5/365 |

550 |

565/585 |

515 |

20-24/20-27 |

HPA240DA/HPA270SR |

|

500 |

20" |

127 |

768 |

330 |

605.8/719 |

260/294 |

319.5/365 |

590 |

620/650 |

565 |

20-24/20-30 |

HPA240DA/HPA270SR |

|

600 |

24" |

151 |

919 |

400 |

719/785 |

294/404 |

365/391 |

695 |

725/770 |

674 |

20-27/20-33 |

HPA270DA/HPA300SR |

2026

/

Choosing a pneumatic angle seat valve shouldn't feel like a guessing game. ...

2026

/

With 15 years of expertise in manufacturing and global trade, Hearken deliv...

2026

/

In 2026, the U.S. solenoid valve market is defined by Smart Manufacturing a...

2026

/

Choosing the right valve is vital for system efficiency. A wrong choice can...

GET A QUOTE