How to Choose the Right Pneumatic Actuator for Your Application?

How to select the right pneumatic actuator?

In today's industrial landscape, pneumatic actuators serve as the backbone of valve automation systems across critical sectors. These robust devices convert compressed air into mechanical motion, enabling precise control of valves in demanding environments. However, with varying operational requirements and industry standards, selecting the optimal pneumatic actuator requires careful consideration of multiple technical factors.

Key factors in selecting a pneumatic actuator

1. Operating Conditions & Certifications

The operating environment plays a pivotal role in actuator selection. For hazardous locations with explosive atmospheres, ATEX-certified actuators are mandatory to ensure safe operation. Similarly, applications exposed to harsh weather or underwater conditions demand IP68-rated actuators with superior sealing against moisture and dust ingress. In safety-critical processes like chemical handling or power generation, SIL3-certified actuators provide the necessary fail-safe reliability.

2. Actuator Type & Movement

Different valve types require specific actuator configurations:

Rack & Pinion actuators excel in quarter-turn applications like ball and butterfly valves, offering smooth 90° rotation

Scotch Yoke designs deliver higher torque output for heavy-duty gate valves

Linear actuators provide the straight-line motion needed for globe and angle seat valves

The choice between spring return (single acting) and double acting models depends on safety requirements - spring return actuators automatically revert to a safe position during air failure, while double acting versions offer faster response times.

3. Material & Durability

Component materials directly impact actuator longevity:

Hard-anodized aluminum alloy bodies resist corrosion in chemical environments

Nickel-plated alloy steel piston shafts minimize friction for smoother operation

High-tensile alloy steel springs maintain consistent force over millions of cycles

4. Performance & Lifespan

HEARKEN actuators undergo rigorous testing to ensure:

1 million+ operation cycles without performance degradation

Precise 90°±5° rotation for accurate valve positioning

Leak-proof seals that maintain optimal air pressure efficiency

5. Customization & Accessories

Modern automation systems often require additional features:

ISO 5211 mounting interfaces for universal valve compatibility

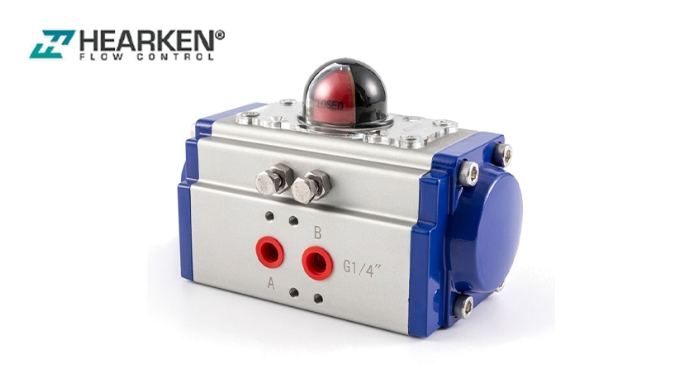

Visual position indicators for quick status verification

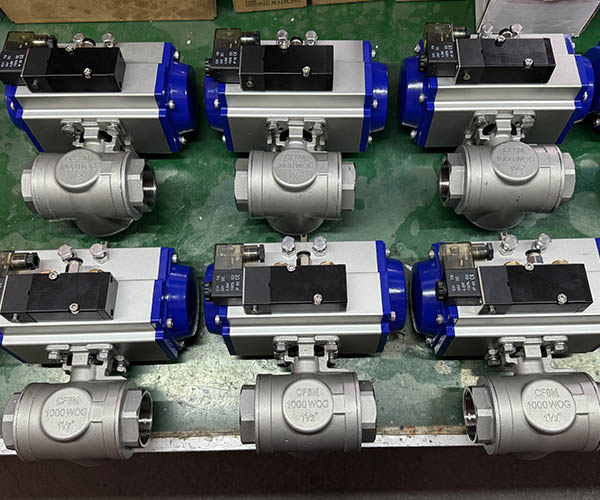

Integrated solenoid valves and limit switches for automated control systems

Air filter regulators to ensure clean, stable air supply

Why HEARKEN Stands Out in Pneumatic Actuation

With over a decade of specialization in valve automation, HEARKEN has established itself as a premier provider of high-performance pneumatic actuators. Our commitment to excellence manifests in several key areas:

Engineering Excellence & Quality Assurance

Every HEARKEN actuator is precision-engineered to deliver unmatched reliability, undergoing rigorous testing including dimensional verification with CMMs, million-cycle endurance tests, digital leakage analysis, and material composition checks. Our comprehensive portfolio spans from standard AT Series rack-and-pinion actuators to explosion-proof, high-torque, and fully customized solutions - all designed to meet stringent global certifications including ATEX, SIL3, ISO 5211, and IP68 standards.

Customer-Focused Technical Support

We go beyond manufacturing to provide complete automation solutions, offering 24/7 engineering support, rapid prototyping for custom applications, on-site commissioning assistance, and readily available spare parts. This holistic approach ensures seamless integration and long-term performance of our actuators in your specific operational environment.

Making the Right Choice for Your Operation

Selecting pneumatic actuators involves balancing technical requirements with operational realities. For standard applications, our AT Series rack and pinion actuators provide reliable performance at competitive prices. Challenging environments may require our explosion-proof or high-cycle variants with enhanced materials.

Conclusion

In an era where operational efficiency and safety compliance are paramount, HEARKEN's pneumatic actuators deliver proven performance across industries. Our combination of engineering expertise, rigorous testing protocols, and responsive customer support ensures you receive not just products, but complete valve automation solutions.

Ready to optimize your valve control system? Contact our technical team at info@hearkenflow.com for personalized recommendations tailored to your specific application requirements.