The Types of Solenoid Valve and Main Applications

Uncontrolled fluid flow can lead to system failures, hazardous leaks, and wasted energy. If you use the wrong valve type, your processes will be inefficient and unreliable. Understanding solenoid valve types ensures you achieve instant, precise, and safe fluid automation.

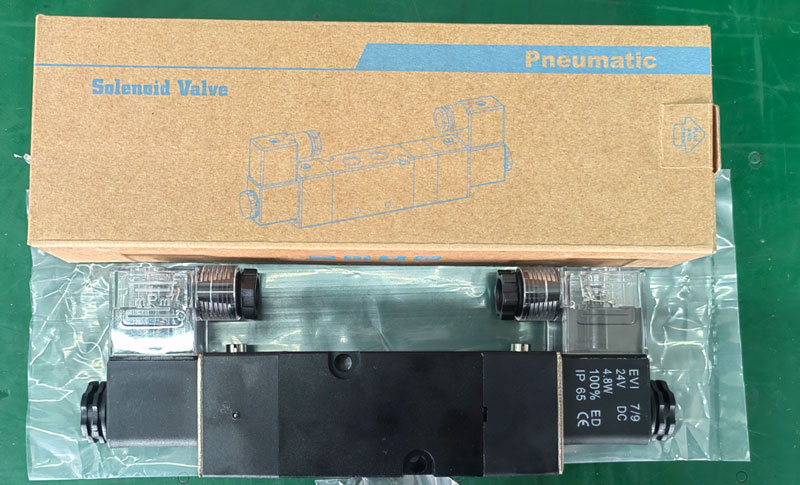

Solenoid valves are essential electromechanical devices used to control the flow of liquids or gases by converting an electrical signal into a mechanical action, making them the most common on/off components in automated systems. They come in various designs—direct-acting, pilot-operated, or semi-direct—each optimized for specific pressure, flow, and response requirements.

To select the perfect component for your specific needs, you need to understand the mechanics. Keep reading for our expert guide.

The Importance of Solenoid Valve

The solenoid valve is indispensable across nearly every automated sector because it acts as a swift, reliable interface between electronic control and physical fluid movement. Think of it as a digital switch for liquids and gases. Its importance stems from its ability to provide instantaneous on/off control, often remotely, in response to low-power electrical signals from a PLC or microcontroller. This enables rapid sequencing, precise dosing, and critical safety shutdowns in systems ranging from sophisticated process control lines to simple household appliances, directly impacting safety, process speed, and energy consumption.

Brief Description of the Working Principle of Solenoid Valve

A solenoid valve operates on basic electromagnetism. The core component is the solenoid—a coil of wire that generates a magnetic field when an electrical current passes through it. This magnetic field is used to actuate a plunger or armature. When the coil is energized, the magnetic force overcomes a return spring and pulls the plunger, either opening or closing an orifice. When the power is removed, the magnetic field collapses, and the spring forces the plunger back to its original position, reversing the flow state. This simple principle allows for quick, repeatable, and automatic fluid control.

Introduction to Solenoid Valve Types

Direct-acting Solenoid Valve

The direct-acting solenoid valve is the simplest design. It works exactly as described above: the solenoid coil, when energized, directly pulls the plunger to open or close the main orifice. This design does not require any external pressure from the fluid medium itself to operate. This makes direct-acting valves ideal for low-flow, low-pressure, or vacuum applications, as they can operate reliably from zero pressure differential (zero-head). While they offer very fast response times, they generally require a larger, more powerful coil to generate the necessary force to seal or open a larger orifice, limiting their use in high-flow systems.

Pilot-operated Solenoid Valve

The pilot-operated solenoid valve utilizes the pressure differential of the system fluid to assist in its operation, making it highly suitable for higher pressure and higher flow rates. When the coil is energized, it only opens a small pilot orifice. This pilot opening releases pressure from the top of the main diaphragm or piston, causing an imbalance. The higher system pressure beneath the diaphragm then forces the main seal open. Because the solenoid only moves a small pilot plunger, it requires far less electrical power than a direct-acting valve of the same size, but it requires a minimum pressure differential to function correctly.

Step-by-step Direct-acting Solenoid Valve (Semi-Direct Lift)

The step-by-step direct-acting valve, often called semi-direct lift or assisted lift, combines the best features of the previous two types. It can operate from zero pressure differential (like a direct-acting valve), but it also uses internal pressure assistance (like a pilot-operated valve) to handle higher pressures once the main seal is cracked open. The plunger in this design is mechanically linked to the diaphragm or piston, using the magnetic force to lift the main seal directly at low pressure. As flow begins, the pressure differential assists in keeping the valve open, allowing you to control medium to high pressures and high flows without requiring a minimum pressure drop.

Main Application Areas

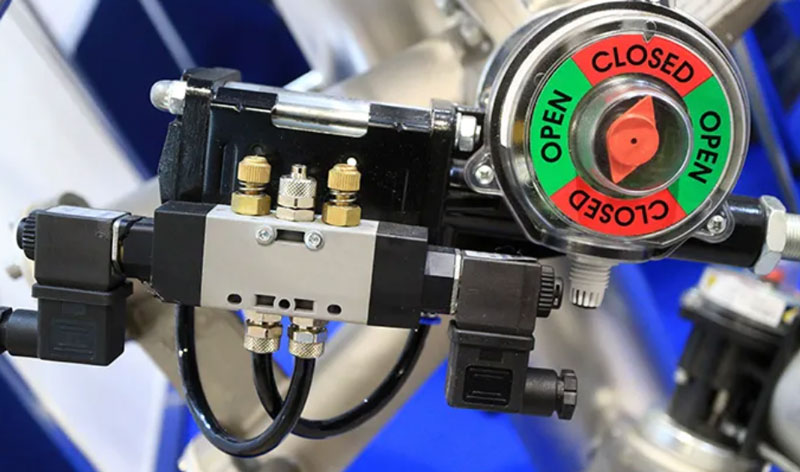

Industrial Field

Your industrial operations rely heavily on solenoid valves for speed and reliability. Covering critical scenarios like the chemical industry, water treatment, and automated production lines, these valves are used to precisely control chemical dosing, manage utility fluid delivery (steam, air), and initiate equipment movement in pneumatic and hydraulic circuits. Their quick response time makes them indispensable in emergency shut-off systems, ensuring immediate process isolation and safety when needed.

Life Field

In the life sector, solenoid valves bring intelligent fluid control right into your home and daily environment. They are key components in modern home appliances, from the automatic water inlet system in your washing machine and dishwasher to the precise gas control in your high-efficiency furnace. In smart home systems, low-power solenoid valves are used in automatic irrigation systems, allowing you to manage garden watering remotely and efficiently based on weather data and schedules.

Transportation Field

The transportation industry depends on these components for both safety and performance. Solenoid valves play a crucial role in automobiles, particularly in automatic transmission control, fuel injection timing, and exhaust gas recirculation (EGR) systems to manage emissions. In rail transportation, they are vital for controlling brake systems (both pneumatic and hydraulic) and managing the precise air delivery needed for door mechanisms and pantographs on electric trains.

Other Fields

The versatility of the solenoid valve extends into highly specialized areas. In medical equipment, miniature, highly precise valves manage minute fluid volumes for drug delivery and analytical instruments, requiring strict material compatibility. In aerospace, robust and often customized solenoid valves control fuel flow to engines, manage pressurization systems within aircraft, and operate fluid circuits in ground support equipment where reliability under extreme temperature fluctuations is non-negotiable.

Key Points for Selecting Solenoid Valves

Consideration Factors

When you select a solenoid valve, several factors are non-negotiable. First, consider the media characteristics, including its viscosity, corrosivity, and temperature, as this determines the required body and seal materials. Next, critically assess the working pressure and flow; this will immediately narrow your choice between direct-acting (low pressure) and pilot-operated (high pressure). Finally, the temperature range of the fluid and the ambient environment influences the coil insulation and seal compatibility, which directly affects the valve's lifespan.

Selection Process

The selection process should be systematic. Start by clarifying your exact needs: is the application on/off, dosing, or safety-related? Second, select the operational type: decide if you need a direct-acting (zero pressure capability), pilot-operated (high pressure, high flow), or semi-direct valve based on your minimum and maximum pressure differential. Third, determine specifications: size the port connection (Cv value is helpful for flow), specify the electrical voltage, and confirm the appropriate body and seal materials for compatibility. Choosing correctly minimizes operational risks and maintenance.

Selecting the right solenoid valve ensures precise automation, maximizing your system’s reliability and efficiency.

FAQ

1. What is the main drawback of using a pilot-operated solenoid valve?

A: The main drawback is that a pilot-operated valve requires a minimum pressure differential (usually 3 to 7 psi) between the inlet and outlet to fully open. If the pressure drops too low, the valve will not function reliably.

2. How can I tell if a solenoid valve is normally open (NO) or normally closed (NC)?

A: A normally closed (NC) valve is closed when power is off, and it opens when power is applied. A normally open (NO) valve is open when power is off, and it closes when power is applied. You must check the manufacturer’s specification to confirm the default state.

3. What does "Cv value" mean, and why is it important for valve selection?

A: The Cv value is the flow coefficient, representing the volume of water (in US gallons per minute) at 60°F that will flow through a valve with a pressure drop of 1 psi. It is critical because it helps you accurately size the valve to meet your required flow rate without excessive pressure loss.

4. Why are direct-acting solenoid valves often used in vacuum applications?

A: Direct-acting valves are the best choice for vacuum or very low-pressure applications because they do not rely on the fluid's pressure differential to operate; the coil's magnetic force directly controls the seal, allowing reliable function at zero or negative pressure.

5. What role does the solenoid valve play in safety systems (e.g., in a boiler)?

A: In safety systems, solenoid valves act as fast-acting shut-off devices. For example, in a boiler, a safety solenoid valve can quickly cut off the fuel supply (gas or oil) immediately upon receiving a signal of low water level or high temperature, preventing dangerous situations.