What are the Advantages of Mini Motorized Valves?

If you need reliable and compact fluid control, you have probably realized ...

HBT rack and pinion pneumatic actuator is prelubricated and tested to a min one million operations. Actuators are available double acting and spring return models. Its meet international ISO5211 standards for easy vale mounting and replacement visual position indicator will monitor the open and closed position.

HBT Rack and pinion pneumatic actuator is a type of actuator that uses compressed air to move a piston that is connected to a rack and pinion mechanism. The rack is a straight, toothed bar, while the pinion is a small, toothed wheel that engages with the rack. When the pneumatic actuator receives a signal, the compressed air enters the piston chamber and pushes the piston, which moves the rack and pinion. As the rack moves, it rotates the pinion, which, in turn, moves the output shaft or valve stem. The output shaft or valve stem is typically mounted on the top of the actuator and moves in a rotational motion to adjust the position of a valve or other control element. This type of actuator is commonly used in process control applications, such as in the oil and gas industry, chemical plants, and power generation plants.

|

Movement: |

Standard adjustable 90°±% |

|

Lubrication: |

All moving parts are lubricated for life-long cycle |

|

Cycle Life: |

1,000,000 Operations |

|

Body: |

Hard anodized extruded Aluminium alloy |

|

Indicator: |

Open/Close Disc |

|

Travel Stops: |

External adjustable±5% in both open/closed position |

|

Springs: |

High tensile spring sets of alloy steel |

|

Piston Shaft: |

Nickel plated alloy steel reduces friction |

|

Piston Guides: |

Self lubricating(Polypropylene+GF)Piston Seals Nitrile** |

|

Piston: |

Die casted aluminium dual piston |

|

End Caps: |

Polyester coated die cast aluminium |

Standard Temperature:-20~+80Degree

Low Temperature:-40~+80Degree

High Temperature:-15~+150

All actuators manufactured by HEARKEN are individually tested. Testing is carried out to check the leakage in both internal and external. The angle of rotation and Torque values. All bodies are stamped with year, month of production, size and serial number.

|

|

|

|

|

|

| Solenoid Valve | Limit Switch Boxes | Electro-pneumatic Positioner | Declutjable Manual Override Gearbox | Hign Visibility Indicator |

|

|

|

|

|

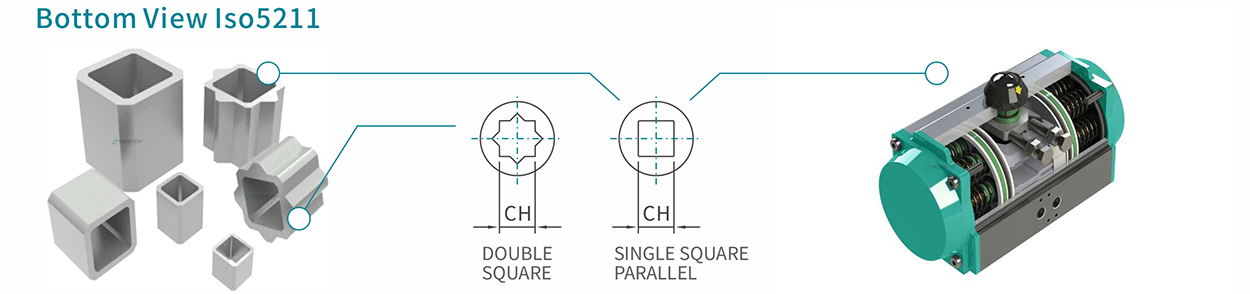

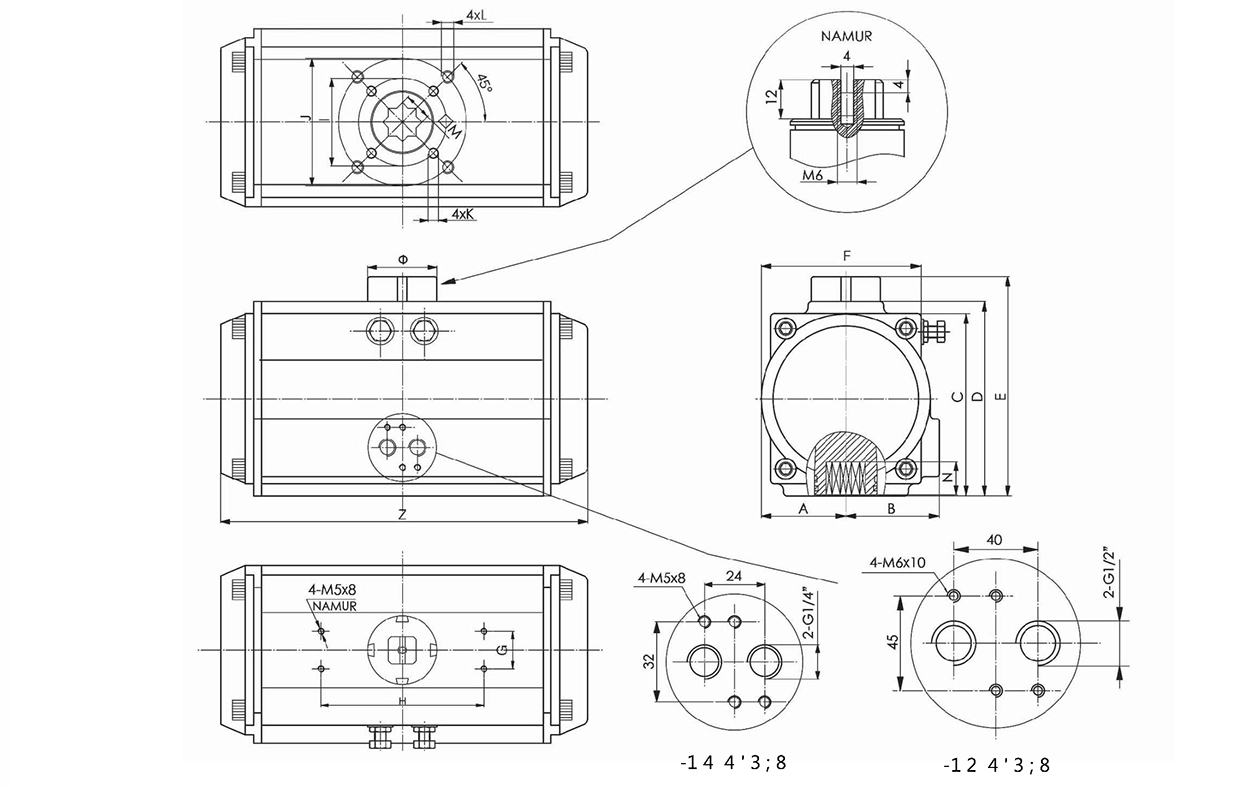

Drive and Flange to ISO5211 |

The NAMUR Drive Pinion and |

Air supply connection is designed |

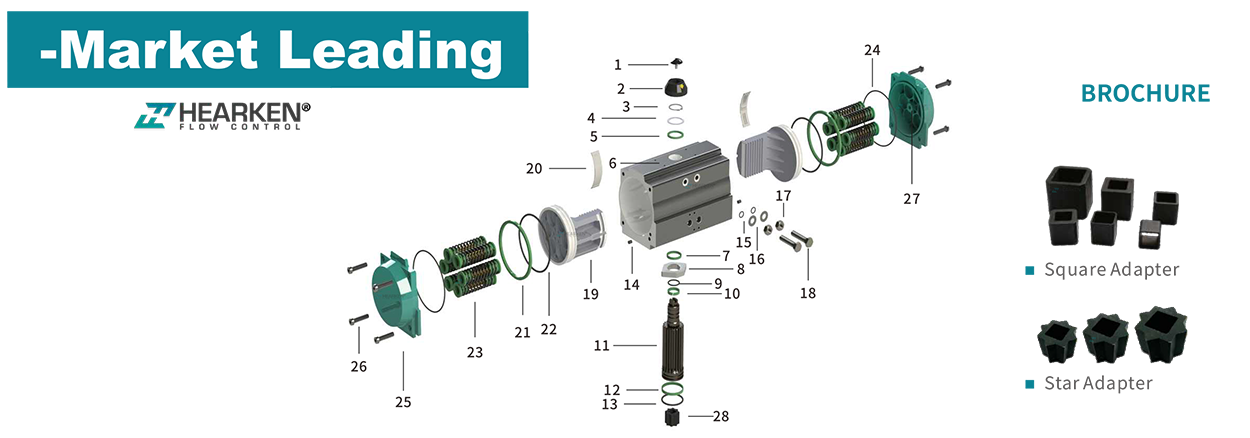

| Description | Material | ty | Description | Material | ty | ||

| 1 | Indicator Screw | ABS | 1 | 15 | O-ring Adjust Screw | N B R (VITON or EPDM on reuest) | 2 |

| 2 | Position Indicator | ABS | 1 | 16 | Washer Adjust Screw | Stainless Steel 304 | 2 |

| 3 | Spring Clip | Stainless Steel 304 | 1 | 17 | N ut Adjust Screw | Stainless Steel 304 | 2 |

| 4 | Metal Washer | Stainless Steel 304 | 1 | 18 | Adjust Screw | Stainless Steel 304 | 2 |

| 5 | OeWr asher | Engineering Plastic | 1 | 19 | Piston | Die Cast Aluminum Alloy | 2 |

| 6 | Body | Extruded Aluminum Alloy | 1 | 20 | Piston B earing | Engineering Plastic/Anodized | 2 |

| 7 | Inner Washer | Engineering Plastic/Hard Anodized | 1 | 21 | Bearing Piston | Engineering Plastic | 2 |

| 8 | Travel Stop | AlloySteel | 1 | 22 | O-ring Piston | N B R (VITON or EPDM on reuest) | 2 |

| 9 | O-ring Pinoin Top | N B R (VITON or EPDM on reuest) | 1 | 23 | Spring Group | Spring Steel | 0~12 |

| 10 | Bearing Pinoin Top | Engineering Plastic | 1 | 24 | O-ring End Cap | N B R (VITON or EPDM on reuest) | 2 |

| 11 | Pinion | AlloySteel (Electroless Nickel Plated) /SS304 is Optional | 1 | 25 | End Cap | Cast Aluminum/Polyester Paint | 2 |

| 12 | Bearing | Engineering Plastic | 1 | 26 | Cap Screw | Stainless Steel 304 | 8 |

| 13 | Bearing Pinoin bottom | N B R (VITON or EPDM on reuest) | 1 | 27 | Stop Screw | Stainless Steel 304 | 2 |

| 14 | Hole Sealant | N B R (VITON or EPDM on reuest) | 2 | 28 | Star Adaptor | Carobon Steel | 1 |

Anodized cylinder body refers to the surface of the cylinder body is anodized to form a layer of coating with wear resistance, corrosion resistance, high hardness and high heat resistance. It can enhance the service life and performance of the cylinder block, and is suitable for working in harsh environments such as high pressure, high temperature, and high corrosion. In addition, anodic hardening can also improve the lubricity and dimensional accuracy of the cylinder, making it more suitable for the use of precision machinery.

The double-piston rack-and-pinion structure makes it compact in structure, symmetrical in installation, long in service life and fast in action. Reversible in the field by simply flipping the piston, the piston is anodized for greater corrosion and wear resistance.

As a standard actuator, the travel limit is adjustable from -5° to 10° in the closed position and -5° to 10° in the open position. In this way, the valve stroke can be adjusted accurately, the stroke can be set and a large stroke adjustment range can be provided.

It is easy to switch between parallel squares and diagonal squares, and double square structure (diagonal and parallel) drive shafts are also available. These two solutions facilitate more flexible and lower inventory.

In relatively high temperature occasions, the top aluminum alloy adapter connected to the accessory is more accurate and stable when matched with the accessory drive shaft. It is suitable for both single square (diagonal or parallel) and double square structure drive shafts and both able to provide.

Double-acting and spring return (single-acting) actuators have the same cylinder and end cover to reduce inventory, and the action mode can be changed in the field by adding and removing spring assembly modules.

he new top adapter is combined with the new valve position indicator, and the position indication of the actuator/valve can be easily adjusted by simply rotating the top adapter and the position indicator 90°. This operation can also be conveniently done on site without dismantling the actuator.

Composite bearings on piston and rack provide precise operation, low friction, and long life. The piston guide ring prevents the output shaft from breaking.

The spring seat of the high-grade coated steel structure is single and versatile, which is safer and corrosion-resistant.

Fracture-resistant construction, bearing guidance for increased safety and maximum service life of the drive shaft.

Piston rack and drive shaft gear can achieve precise positioning, small backlash and maximum meshing can achieve high-efficiency operation in the whole process.

Wide operating temperature range, low friction, long life.

Stainless steel bolt fasteners provide long-term corrosion resistance.

The products provided are in full compliance with international standards such as ISO5211, DIN3337 and VID/VED3845, which can better achieve interchangeability and more convenient installation of valves and various accessories.

| Model | DA Weight (Kgs) |

SR Weight (Kgs) |

Air Volume opening | Air Volume closing | Model | DA Weight (Kgs) |

SR Weight (Kgs) |

Air Volume opening | Air Volume closing | Model | DA Weight (Kgs) |

SR Weight (Kgs) |

Air Volume opening | Air Volume closing |

| DA/SR 032 | 0.7 | - | 0.04 | 0.05 | DA/SR 092 | 4.6 | 5.2 | 0.64 | 0.473 | DA/SR 210 | 47 | 55 | 7.5 | 7.5 |

| DA/SR 040 | 1 | 1.1 | 0.08 | 0.11 | DA/SR 105 | 6.8 | 6.9 | 0.95 | 0.88 | DA/SR 240 | 67 | 80 | 11 | 9 |

| DA/SR 052 | 1.4 | 1.5 | 0.12 | 0.16 | DA/SR 125 | 8.9 | 10.1 | 1.6 | 1.4 | DA/SR 270 | 97 | 118 | 17 | 14 |

| DA/SR 063 | 2 | 2.1 | 0.21 | 0.23 | DA/SR 140 | 13 | 15 | 2.5 | 2.2 | DA/SR 300 | 110 | 130 | 23.8 | 29.7 |

| DA/SR 063 | 2.7 | 2.9 | 0.3 | 0.34 | DA/SR 063 | 20 | 24 | 3.7 | 3.2 | DA/SR 350 | 186 | 234 | 35.1 | 46.3 |

| DA/SR 083 | 3.1 | 3.6 | 0.43 | 0.47 | DA/SR 190 | 31 | 35 | 5.9 | 5.4 | DA/SR 400 | 289 | 360 | 52.6 | 56 |

| Model | DA Weight (Kgs) | SR Weight (Kgs) | Air volume opening | Air volume closing | Model | DA Weight (Kgs) | SR Weight (Kgs) | Air volume opening | Air volume closing |

| 32 | 0.7 | - | 0.04 | 0.05 | 140 | 13 | 15 | 2.5 | 2.2 |

| 40 | 1 | 1.1 | 0.08 | 0.11 | 160 | 20 | 24 | 3.7 | 3.2 |

| 52 | 1.4 | 1.5 | 0.12 | 0.16 | 190 | 31 | 35 | 5.9 | 5.4 |

| 63 | 2 | 2.1 | 0.21 | 0.23 | 210 | 47 | 55 | 7.5 | 7.5 |

| 75 | 2.7 | 2.9 | 0.3 | 0.34 | 240 | 67 | 80 | 11 | 9 |

| 83 | 3.1 | 3.6 | 0.43 | 0.47 | 270 | 97 | 118 | 17 | 14 |

| 92 | 4.6 | 5.2 | 0.64 | 0.473 | 300 | 110 | 130 | 23.8 | 29.7 |

| 105 | 6.8 | 6.9 | 0.95 | 0.88 | 350 | 186 | 234 | 35.1 | 46.3 |

| 125 | 8.9 | 10.1 | 1.6 | 1.4 | 400 | 289 | 360 | 52.6 | 56 |

| Model | Air supply pressure(Unit:bar) | |||||||||

| 2 | 2.5 | 3 | 4 | 4.5 | 5 | 5.5 | 6 | 7 | 8 | |

| HBT032DA | 3 | 4 | 5 | 6 | 7 | 8 | 8 | 9 | 11 | 12 |

| HBT040DA | 5 | 6 | 7 | 10 | 11 | 12 | 13 | 14 | 17 | 19 |

| HBT052DA | 8 | 10 | 12 | 16 | 18 | 20 | 22 | 24 | 28 | 32 |

| HBT063DA | 15 | 18 | 22 | 29 | 33 | 36 | 40 | 44 | 51 | 58 |

| HBT075DA | 20 | 25 | 30 | 40 | 45 | 50 | 55 | 60 | 70 | 80 |

| HBT083DA | 31 | 39 | 47 | 63 | 70 | 78 | 86 | 94 | 110 | 125 |

| HBT092DA | 45 | 56 | 68 | 90 | 102 | 113 | 124 | 135 | 158 | 181 |

| HBT105DA | 66 | 83 | 99 | 132 | 149 | 165 | 182 | 198 | 231 | 264 |

| HBT125DA | 100 | 125 | 150 | 200 | 226 | 251 | 276 | 301 | 351 | 401 |

| HBT140DA | 171 | 214 | 256 | 342 | 385 | 427 | 470 | 513 | 598 | 684 |

| HBT160DA | 266 | 332 | 399 | 532 | 598 | 665 | 731 | 798 | 931 | 1064 |

| HBT190DA | 426 | 532 | 638 | 851 | 958 | 1064 | 1170 | 1277 | 1490 | 1702 |

| HBT210DA | 532 | 665 | 798 | 1064 | 1197 | 1330 | 1463 | 1596 | 1862 | 2128 |

| HBT240DA | 769 | 932 | 1154 | 1539 | 1731 | 1924 | 2116 | 2308 | 2693 | 3078 |

| HBT270DA | 1170 | 1462 | 1754 | 2339 | 2632 | 2924 | 3216 | 3509 | 4094 | 4679 |

| HBT300DA | 1526 | 1908 | 2289 | 3052 | 3434 | 3815 | 4197 | 4578 | 5341 | 6104 |

| HBT350DA | 2285 | 2856 | 3427 | 4570 | 5141 | 5712 | 6283 | 6854 | 997 | 9139 |

| HBT400DA | 3256 | 4070 | 4884 | 6512 | 7326 | 8140 | 8954 | 9768 | 11396 | 13024 |

| Unit:N.m | |||||||||||||||||

| Output torque of air springs | Spring's output | ||||||||||||||||

| Air pressure | 2.5BAR | 3BAR | 4BAR | 5BAR | 6BAR | 7BAR | 8BAR | ||||||||||

| Model | Spring Qty. | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 90° | 0° |

| Start | End | Start | End | Start | End | Start | End | Start | End | Start | End | Start | End | Start | End | ||

| HBT-52SR | 5 | 5.7 | 3.8 | 7.6 | 5.7 | 6.2 | 4.3 | ||||||||||

| 6 | 4.9 | 2.5 | 6.9 | 4.5 | 10.9 | 8.5 | 7.4 | 5 | |||||||||

| 7 | 4 | 1.3 | 6 | 3.3 | 9.8 | 7.3 | 14 | 10.4 | 8.6 | 5.9 | |||||||

| 8 | 5.2 | 2 | 9.2 | 6 | 13.2 | 9.1 | 17.2 | 14.1 | 9.9 | 6.7 | |||||||

| 9 | 4.3 | 0.8 | 8.3 | 4.8 | 12.3 | 7.9 | 16.3 | 12.8 | 20.3 | 16.8 | 11.1 | 7.6 | |||||

| 10 | 7.4 | 3.6 | 11.5 | 6.7 | 15.5 | 11.6 | 19.5 | 15.6 | 12.4 | 8.5 | |||||||

| 11 | 6.6 | 2.3 | 10.6 | 5.4 | 14.6 | 10.4 | 18.6 | 14.3 | 22.6 | 18.3 | 13.6 | 9.3 | |||||

| 12 | 9.7 | 4.2 | 13.8 | 9.1 | 17.8 | 12.2 | 21.8 | 17.1 | 14.8 | 10.2 | |||||||

| HBT-63SR | 5 | 11.4 | 7.7 | 15 | 11.4 | 22.3 | 14.9 | 10.4 | 6.8 | ||||||||

| 6 | 10.1 | 5.7 | 13.6 | 9.3 | 20.9 | 16.6 | 28.3 | 23.9 | 12.5 | 8.2 | |||||||

| 7 | 8.6 | 3.6 | 12.5 | 7.2 | 19.5 | 14.5 | 26.8 | 21.9 | 14.6 | 9.6 | |||||||

| 8 | 10.9 | 5.1 | 18.2 | 12.4 | 25.5 | 19.8 | 32.8 | 27 | 40.1 | 34.3 | 16.7 | 10.9 | |||||

| 9 | 16.8 | 10.4 | 24.1 | 17.7 | 31.4 | 24.9 | 38.7 | 32.2 | 18.8 | 12.3 | |||||||

| 10 | 1.4 | 8.2 | 22.8 | 15.6 | 30 | 22.8 | 37.3 | 30.1 | 44.7 | 37.4 | 20.9 | 13.7 | |||||

| 11 | 21.5 | 13.5 | 28.7 | 20.7 | 36 | 28 | 43.3 | 35.3 | 22.9 | 15 | |||||||

| 12 | 20 | 11.4 | 27.3 | 18.6 | 34.6 | 25.9 | 41.9 | 33.3 | 25 | 16.4 | |||||||

| HBT-75SR | 5 | 14.5 | 10.5 | 19.4 | 15.5 | 29.5 | 25.7 | 14.5 | 10.5 | ||||||||

| 6 | 12.4 | 7.6 | 17.3 | 12.6 | 27.4 | 22.7 | 37.5 | 32.8 | 17.4 | 12.7 | |||||||

| 7 | 10.4 | 4.8 | 15.2 | 9.7 | 25.3 | 19.9 | 35.4 | 29.9 | 20.3 | 14.8 | |||||||

| 8 | 13.1 | 6.8 | 23.1 | 16.9 | 33.3 | 27 | 43.2 | 37 | 53.3 | 47 | 23.2 | 16.9 | |||||

| 9 | 21 | 14.1 | 31.2 | 24.1 | 41.1 | 34.1 | 51.2 | 44.2 | 26.1 | 19 | |||||||

| 10 | 19 | 11.1 | 28.8 | 21.2 | 39 | 31.2 | 49.1 | 41.2 | 59.1 | 51.2 | 29 | 21.1 | |||||

| 11 | 27 | 18.3 | 37 | 28.3 | 47 | 38.4 | 57 | 48.4 | 31.9 | 23.2 | |||||||

| 12 | 24.9 | 15.4 | 34.9 | 25.4 | 44.9 | 35.4 | 54.9 | 45.4 | 34.7 | 25.3 | |||||||

| HBT-83SR | 5 | 23.3 | 16.1 | 31.1 | 24 | 46.8 | 39.7 | 23 | 15.8 | ||||||||

| 6 | 20.1 | 11.5 | 28 | 19.3 | 43.7 | 35.1 | 59.4 | 50.7 | 27.6 | 19 | |||||||

| 7 | 17 | 6.9 | 24.8 | 14.8 | 40.5 | 30.5 | 56.2 | 46.2 | 32.2 | 22.1 | |||||||

| 8 | 21.7 | 10.1 | 37.4 | 25.8 | 53.1 | 41.5 | 68.8 | 57.2 | 84.5 | 72.9 | 36.8 | 23.2 | |||||

| 9 | 34.2 | 21.3 | 49.9 | 37 | 65.6 | 52.6 | 81.2 | 68.3 | 41.4 | 28.5 | |||||||

| 10 | 31 | 16.6 | 46.7 | 32.3 | 62.4 | 48 | 78.1 | 63.7 | 93.8 | 79.3 | 46 | 31.6 | |||||

| 11 | 43.6 | 27.7 | 59.3 | 43.4 | 75 | 59.1 | 90.6 | 74.8 | 50.6 | 34.8 | |||||||

| 12 | 40.4 | 23.2 | 56.1 | 38.9 | 71.7 | 54.5 | 87.4 | 70.2 | 55.2 | 38 | |||||||

| HBT-92SR | 5 | 33.1 | 22 | 44.2 | 33.2 | 66.8 | 55.9 | 34.4 | 23.3 | ||||||||

| 6 | 28.4 | 15.2 | 39.6 | 26.4 | 62.2 | 49 | 84.8 | 71.6 | 41.2 | 28 | |||||||

| 7 | 23.8 | 8.2 | 34.9 | 19.4 | 57.5 | 42.1 | 80.2 | 64.7 | 48.1 | 32.7 | |||||||

| 8 | 31.3 | 12.6 | 52.9 | 35.2 | 75.5 | 57.9 | 98.1 | 80.5 | 120.7 | 103 | 55 | 37.3 | |||||

| 9 | 48.2 | 28.4 | 709 | 51 | 93.5 | 73.6 | 116 | 96.1 | 61.9 | 42 | |||||||

| 10 | 43.6 | 21.5 | 66.2 | 44.1 | 88.8 | 66.7 | 111.3 | 89.2 | 134 | 111.8 | 68.7 | 46.7 | |||||

| 11 | 61.5 | 37.2 | 84.1 | 59.9 | 106.6 | 82.4 | 129.2 | 105 | 75.6 | 51.4 | |||||||

| 12 | 56.8 | 30.4 | 79.4 | 53 | 101.9 | 75.5 | 124.5 | 98.1 | 82.5 | 56 | |||||||

| HBT-105SR | 5 | 51 | 33.4 | 67.5 | 49.9 | 100.6 | 83 | 124.5 | 49.2 | 31.6 | |||||||

| 6 | 44.7 | 23.5 | 61.1 | 40 | 94.2 | 73.2 | 127.3 | 106.2 | 59.1 | 38 | |||||||

| 7 | 38.4 | 13.7 | 54.9 | 30.3 | 87.9 | 63.4 | 121 | 96.4 | 68.9 | 44.3 | |||||||

| 8 | 48.5 | 20.4 | 81.6 | 53.5 | 114.7 | 86.5 | 147.7 | 119.6 | 180.8 | 152.7 | 78.7 | 50.6 | |||||

| 9 | 75.3 | 43.7 | 108.4 | 76.8 | 141.5 | 109.8 | 174.5 | 142.9 | 88.6 | 56.9 | |||||||

| 10 | 68.9 | 33.4 | 102 | 66.5 | 135.1 | 99.6 | 168.2 | 132.6 | 201.2 | 165.7 | 98.4 | 63.3 | |||||

| 11 | 95.7 | 57 | 127.7 | 90.1 | 161.8 | 123.1 | 194.8 | 156.2 | 108.3 | 69.6 | |||||||

| 12 | 89.4 | 47.5 | 122.5 | 80.6 | 155.5 | 113.6 | 188.6 | 146.7 | 118.1 | 75.9 | |||||||

| HBT-125SR | 5 | 73 | 47 | 98 | 72 | 148 | 122 | 79 | 52 | ||||||||

| 6 | 63 | 31 | 88 | 56 | 138 | 107 | 188 | 157 | 94 | 63 | |||||||

| 7 | 52 | 15 | 77 | 40 | 127 | 90 | 178 | 141 | 110 | 73 | |||||||

| 8 | 67 | 25 | 117 | 75 | 167 | 125 | 217 | 176 | 268 | 226 | 125 | 84 | |||||

| 9 | 107 | 59 | 157 | 109 | 207 | 159 | 257 | 210 | 141 | 94 | |||||||

| 10 | 96 | 44 | 146 | 94 | 196 | 144 | 247 | 194 | 297 | 245 | 157 | 105 | |||||

| 11 | 136 | 78 | 186 | 128 | 236 | 178 | 286 | 228 | 173 | 115 | |||||||

| 12 | 125 | 63 | 176 | 113 | 226 | 163 | 276 | 213 | 188 | 125 | |||||||

| HBT-140SR | 5 | 128 | 85 | 171 | 127 | 256 | 213 | 129 | 86 | ||||||||

| 6 | 111 | 59 | 154 | 102 | 239 | 187 | 325 | 273 | 155 | 103 | |||||||

| 7 | 94 | 33 | 137 | 76 | 222 | 162 | 308 | 247 | 181 | 120 | |||||||

| 8 | 120 | 50 | 205 | 136 | 291 | 221 | 376 | 307 | 462 | 392 | 206 | 137 | |||||

| 9 | 187 | 110 | 273 | 196 | 358 | 281 | 444 | 367 | 232 | 155 | |||||||

| 10 | 170 | 84 | 256 | 169 | 341 | 255 | 427 | 340 | 512 | 426 | 258 | 172 | |||||

| 11 | 238 | 143 | 324 | 229 | 409 | 314 | 495 | 400 | 284 | 189 | |||||||

| 12 | 221 | 118 | 307 | 203 | 392 | 289 | 478 | 374 | 310 | 206 | |||||||

| HBT160SR | 5 | 193 | 124 | 259 | 191 | 392 | 324 | 208 | 140 | ||||||||

| 6 | 165 | 83 | 232 | 149 | 365 | 282 | 498 | 415 | 250 | 168 | |||||||

| 7 | 137 | 41 | 203 | 107 | 336 | 240 | 469 | 373 | 292 | 196 | |||||||

| 8 | 176 | 66 | 309 | 199 | 442 | 237 | 575 | 465 | 708 | 598 | 333 | 223 | |||||

| 9 | 280 | 157 | 413 | 290 | 546 | 423 | 679 | 556 | 375 | 251 | |||||||

| 10 | 253 | 115 | 386 | 248 | 519 | 381 | 652 | 514 | 785 | 647 | 417 | 279 | |||||

| 11 | 358 | 207 | 491 | 340 | 624 | 473 | 757 | 606 | 458 | 307 | |||||||

| 12 | 330 | 165 | 463 | 298 | 596 | 431 | 729 | 564 | 500 | 335 | |||||||

| HBT190SR | 5 | 332 | 222 | 438 | 329 | 651 | 542 | 309 | 200 | ||||||||

| 6 | 292 | 161 | 398 | 267 | 611 | 480 | 824 | 693 | 371 | 240 | |||||||

| 7 | 252 | 99 | 358 | 205 | 571 | 418 | 784 | 631 | 433 | 280 | |||||||

| 8 | 318 | 143 | 531 | 356 | 744 | 569 | 957 | 782 | 1169 | 995 | 495 | 320 | |||||

| 9 | 491 | 295 | 704 | 507 | 917 | 720 | 1130 | 933 | 557 | 360 | |||||||

| 10 | 451 | 233 | 664 | 446 | 877 | 658 | 1090 | 871 | 1302 | 1084 | 618 | 400 | |||||

| 11 | 624 | 384 | 837 | 597 | 1050 | 809 | 1263 | 1022 | 680 | 440 | |||||||

| 12 | 584 | 322 | 797 | 535 | 1010 | 748 | 1223 | 960 | 742 | 480 | |||||||

| HBT210SR | 5 | 390 | 285 | 523 | 418 | 789 | 684 | 380 | 275 | ||||||||

| 6 | 335 | 209 | 468 | 342 | 734 | 608 | 1000 | 874 | 456 | 330 | |||||||

| 7 | 280 | 133 | 413 | 266 | 679 | 532 | 945 | 798 | 532 | 385 | |||||||

| 8 | 358 | 190 | 624 | 456 | 890 | 722 | 1156 | 988 | 1422 | 1254 | 608 | 440 | |||||

| 9 | 569 | 380 | 835 | 646 | 1101 | 912 | 1367 | 1178 | 684 | 495 | |||||||

| 10 | 514 | 304 | 780 | 570 | 1046 | 836 | 1312 | 1102 | 1578 | 1368 | 760 | 550 | |||||

| 11 | 725 | 494 | 991 | 760 | 1257 | 1026 | 1523 | 1292 | 836 | 605 | |||||||

| 12 | 670 | 418 | 936 | 684 | 1202 | 950 | 1468 | 1216 | 912 | 660 | |||||||

| HBT240SR | 5 | 552 | 409 | 744 | 600 | 1129 | 985 | 554 | 410 | ||||||||

| 6 | 470 | 297 | 662 | 489 | 1047 | 874 | 1432 | 1259 | 665 | 492 | |||||||

| 7 | 388 | 187 | 580 | 379 | 964 | 764 | 1349 | 1149 | 775 | 575 | |||||||

| 8 | 498 | 268 | 883 | 653 | 1267 | 1037 | 1652 | 1422 | 2037 | 1807 | 886 | 656 | |||||

| 9 | 800 | 542 | 1185 | 926 | 1569 | 1311 | 1954 | 1696 | 998 | 739 | |||||||

| 10 | 718 | 431 | 1103 | 816 | 1488 | 1201 | 1874 | 1586 | 2257 | 1970 | 1108 | 821 | |||||

| 11 | 1021 | 705 | 1406 | 1090 | 1791 | 1474 | 2176 | 1859 | 1219 | 903 | |||||||

| 12 | 939 | 594 | 1323 | 979 | 1708 | 1363 | 2093 | 1748 | 1330 | 985 | |||||||

| HBT270SR | 5 | 903 | 675 | 1195 | 968 | 1779 | 1552 | 787 | 560 | ||||||||

| 6 | 790 | 519 | 1083 | 811 | 1667 | 1396 | 2252 | 1984 | 943 | 672 | |||||||

| 7 | 679 | 361 | 972 | 654 | 1556 | 1238 | 2141 | 1823 | 1101 | 783 | |||||||

| 8 | 860 | 497 | 1444 | 1081 | 2029 | 1666 | 2614 | 2252 | 3199 | 2836 | 1258 | 895 | |||||

| 9 | 1332 | 923 | 1917 | 1509 | 2502 | 2094 | 3087 | 2678 | 1416 | 1007 | |||||||

| 10 | 1220 | 767 | 1805 | 1352 | 2390 | 1937 | 2974 | 2521 | 3560 | 3107 | 1572 | 1119 | |||||

| 11 | 1693 | 1194 | 2278 | 1779 | 2862 | 2364 | 3448 | 2949 | 1730 | 1231 | |||||||

| 12 | 1582 | 1037 | 2167 | 1623 | 2751 | 2207 | 3336 | 2792 | 1887 | 1342 | |||||||

| HBT300SR | 5 | 1097 | 729 | 1061 | 730 | ||||||||||||

| 6 | 935 | 494 | 1316 | 875 | 1273 | 876 | |||||||||||

| 7 | 772 | 258 | 1153 | 639 | 1916 | 1402 | 1485 | 1022 | |||||||||

| 8 | 991 | 403 | 1754 | 1166 | 2517 | 1929 | 1697 | 1168 | |||||||||

| 9 | 1592 | 930 | 2355 | 1693 | 3118 | 2456 | 1909 | 1314 | |||||||||

| 10 | 1430 | 695 | 2193 | 1458 | 2956 | 2221 | 3719 | 2984 | 4482 | 3747 | 2122 | 1460 | |||||

| 11 | 2030 | 1222 | 2793 | 1985 | 3556 | 2748 | 4319 | 3511 | 2334 | 1606 | |||||||

| 12 | 1868 | 986 | 2631 | 1749 | 3394 | 2512 | 4157 | 3275 | 2546 | 1752 | |||||||

| HBT350SR | 5 | 1553 | 964 | 1702 | 1173 | ||||||||||||

| 6 | 1292 | 586 | 1863 | 1157 | 2043 | 1408 | |||||||||||

| 7 | 1031 | 208 | 1602 | 779 | 2745 | 1922 | 2383 | 1642 | |||||||||

| 8 | 1341 | 401 | 2484 | 1544 | 3626 | 2686 | 2724 | 1877 | |||||||||

| 9 | 2224 | 1165 | 3336 | 2307 | 4508 | 3449 | 3064 | 212 | |||||||||

| 10 | 1963 | 787 | 3105 | 1929 | 4247 | 3071 | 5390 | 4214 | 6532 | 5356 | 3405 | 2346 | |||||

| 11 | 2844 | 1551 | 3986 | 2693 | 5129 | 336 | 6271 | 4978 | 3745 | 2581 | |||||||

| 12 | 2584 | 1172 | 3726 | 2314 | 4869 | 3457 | 6011 | 4599 | 4086 | 2816 | |||||||

| HBT400SR | 7 | 2028 | 869 | 2880 | 1837 | ||||||||||||

| 8 | 1736 | 411 | 2550 | 1225 | 3292 | 2100 | |||||||||||

| 9 | 2259 | 768 | 3887 | 2396 | 3703 | 2362 | |||||||||||

| 10 | 1967 | 311 | 3595 | 1939 | 5223 | 3567 | 4115 | 2624 | |||||||||

| 11 | 3303 | 1482 | 4931 | 3110 | 6559 | 4738 | 4526 | 2887 | |||||||||

| 12 | 3012 | 1025 | 4640 | 2653 | 6268 | 4281 | 7895 | 5908 | 9523 | 7536 | 4938 | 3149 | |||||

| 13 | 4348 | 2195 | 5976 | 3823 | 7603 | 5450 | 9231 | 7078 | 5349 | 3412 | |||||||

| 14 | 4057 | 1738 | 5685 | 3366 | 7312 | 4993 | 8940 | 6621 | 5761 | 3674 | |||||||

| 15 | 3765 | 1281 | 5393 | 2909 | 7020 | 4536 | 8648 | 6164 | 6172 | 3937 | |||||||

| 16 | 5101 | 2452 | 6728 | 4078 | 8356 | 5707 | 6584 | 4199 | |||||||||

| Model | A | B | C | D | E | F | G | H | I | J | K | L | M | N | Z | Φ | Air Connection | Flange Size |

| DA/SR-32 | 23 | 23 | 46 | 46 | 66 | 46 | 25 | 50 | Φ36 | M5x8 | 9 | 11 | 110 | Φ40 | NAMUR G1/4" | F03/F05 | ||

| DA/SR-40 | 28.5 | 36.5 | 60 | 60 | 80 | 52 | 30 | 80 | Φ36 | Φ50 | M5x8 | M6x10 | 11 | 14 | 122 | Φ40 | NAMUR G1/4" | F03/F05 |

| DA/SR-52 | 30 | 41.5 | 65.5 | 72 | 92 | 65 | 30 | 80 | Φ36 | Φ50 | M5x8 | M6x10 | 11 | 14 | 147 | Φ40 | NAMUR G1/4" | F03/F05 |

| DA/SR-63 | 36 | 47 | 81 | 88 | 108 | 72 | 30 | 80 | Φ50 | Φ70 | M6x10 | M8x13 | 14 | 18 | 168 | Φ40 | NAMUR G1/4" | F05/F07 |

| DA/SR-75 | 42 | 53 | 94 | 99.5 | 119.5 | 81 | 30 | 80 | Φ50 | Φ70 | M6x10 | M8x13 | 14 | 18 | 184 | Φ40 | NAMUR G1/4" | F05/F07 |

| DA/SR-83 | 46 | 57 | 98.5 | 108.7 | 128.7 | 92 | 30 | 80 | Φ50 | Φ70 | M6x10 | M8x13 | 17 | 21 | 204 | Φ40 | NAMUR G1/4" | F05/F07 |

| DA/SR-92 | 50 | 58.5 | 111 | 116.5 | 136.5 | 98 | 30 | 80 | Φ50 | Φ70 | M6x10 | M8x13 | 17 | 21 | 262 | Φ40 | NAMUR G1/4" | F05/F07 |

| DA/SR-105 | 57.5 | 64 | 122.5 | 133 | 153 | 109.5 | 30 | 80 | Φ70 | Φ102 | M8x13 | M10x16 | 22 | 26 | 268 | Φ40 | NAMUR G1/4" | F07/F10 |

| DA/SR-125 | 67.5 | 74.5 | 145.5 | 155 | 185 | 127.5 | 30 | 130 | Φ70 | Φ102 | M8x13 | M10x16 | 22 | 26 | 301 | Φ55 | NAMUR G1/4" | F07/F10 |

| DA/SR-140 | 75 | 77 | 161 | 172 | 202 | 137.5 | 30 | 130 | Φ102 | Φ125 | M10x16 | M12x20 | 27 | 31 | 390 | Φ55 | NAMUR G1/4" | F10/F12 |

| DA/SR-160 | 87 | 87 | 184 | 197 | 227 | 159 | 30 | 130 | Φ102 | Φ125 | M10x16 | M12x20 | 27 | 31 | 458 | Φ55 | NAMUR G1/4" | F10/F12 |

| DA/SR-190 | 103 | 103 | 215 | 230 | 260 | 189 | 30 | 130 | Φ140 | M16x25 | 36 | 40 | 525 | Φ80 | NAMUR G1/4" | F14 | ||

| DA/SR-210 | 113 | 113 | 235.5 | 255 | 285 | 210 | 30 | 130 | Φ140 | M16x25 | 36 | 40 | 532 | Φ80 | NAMUR G1/4" | F14 | ||

| DA/SR-240 | 130 | 130 | 264.5 | 289 | 319 | 245 | 30 | 130 | Φ165 | M20x25 | 46 | 50 | 602 | Φ80 | NAMUR G1/4" | F16 | ||

| DA/SR-270 | 147 | 147 | 299 | 326 | 356 | 273 | 30 | 130 | Φ165 | M20x25 | 46 | 50 | 718 | Φ80 | NAMUR G1/2" | F16 | ||

| DA/SR-300 | 162 | 174 | 330 | 350 | 380 | 312 | 30 | 130 | Φ165 | M20x25 | 46 | 50 | 760 | Φ80 | NAMUR G1/2" | F16 | ||

| DA/SR-350 | 190 | 195 | 483 | 410 | 440 | 365 | 30 | 130 | Φ254 | M20x25 | 8xM16x25 | 46 | 50 | 920 | Φ80 | NAMUR G1/2" | F16/F25 | |

| DA/SR-400 | 260 | 260 | 466 | 466 | 496 | 298 | 30 | 130 | Φ254 | M20x25 | 8xM16x25 | 46 | 50 | 940 | Φ80 | NAMUR G1/2" | F16/F25 |

2026

/

If you need reliable and compact fluid control, you have probably realized ...

2026

/

Modern piping is changing fast. Automation is now replacing manual valves i...

2026

/

In the industrial landscape of 2026, the demand for precision flow control ...

2026

/

Efficiency is the top priority in any modern piping system. You need compon...

GET A QUOTE