How to Select the Right Pneumatic Angle Seat Valve: A Comprehensive Buyer’s Guide

Choosing a pneumatic angle seat valve shouldn't feel like a guessing game. ...

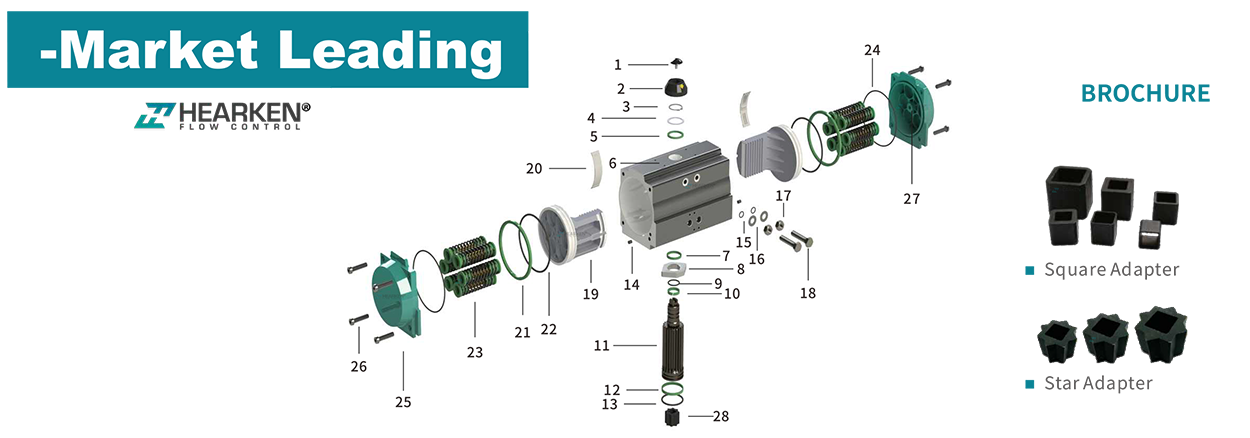

Hearken double acting pneumatic actuator has efficient output torque and smooth operation in a compact design which suited for the operation of ball valve, butterfly valve etc…the body is made of extruded aluminum and the end caps are die cast. Every hearken actuator is 100% factory pressure tested to ensure the highest quality pneumatic actuator is achieved. Provides valve accessories, including limit switches, positioners, solenoid valves and mounting bracket and coupling.

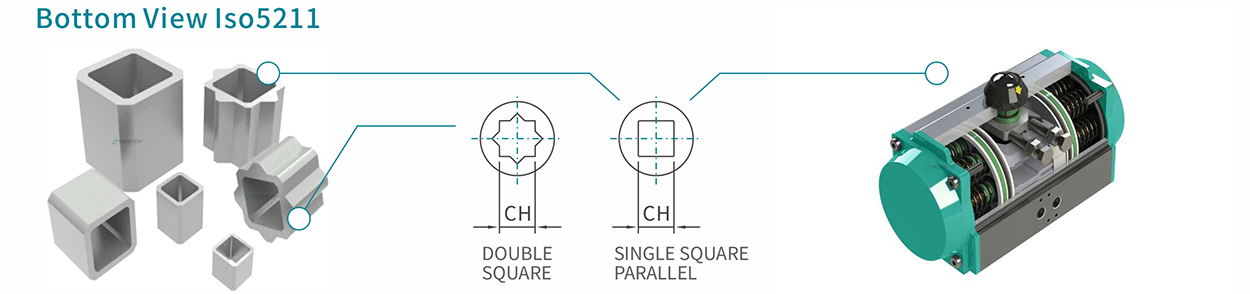

HPA Double Acting Pneumatic Actuator is prelubricated and tested to a min one million operations. Actuators are available double acting and spring return models. Its meet international ISO5211 standards for easy vale mounting and replacement visual position indicator will monitor the open and closed position.

|

Movement: |

Standard adjustable 90°±% |

|

Lubrication: |

All moving parts are lubricated for life-long cycle |

|

Cycle Life: |

1,000,000 Operations |

|

Body: |

Hard anodized extruded Aluminium alloy |

|

Indicator: |

Open/Close Disc |

|

Travel Stops: |

External adjustable±5% in both open/closed position |

|

Springs: |

High tensile spring sets of alloy steel |

|

Piston Shaft: |

Nickel plated alloy steel reduces friction |

|

Piston Guides: |

Self lubricating(Polypropylene+GF)Piston Seals Nitrile** |

|

Piston: |

Die casted aluminium dual piston |

|

End Caps: |

Polyester coated die cast aluminium |

Standard Temperature:-20~+80Degree

Low Temperature:-40~+80Degree

High Temperature:-15~+150

All actuators manufactured by HEARKEN are individually tested. Testing is carried out to check the leakage in both internal and external. The angle of rotation and Torque values. All bodies are stamped with year, month of production, size and serial number.

|

|

|

|

|

|

| Solenoid Valve | Limit Switch Boxes | Electro-pneumatic Positioner | Declutjable Manual Override Gearbox | Hign Visibility Indicator |

|

|

|

|

|

Drive and Flange to ISO5211 |

The NAMUR Drive Pinion and |

Air supply connection is designed |

| Description | Material | ty | Description | Material | ty | ||

| 1 | Indicator Screw | ABS | 1 | 15 | O-ring Adjust Screw | N B R (VITON or EPDM on reuest) | 2 |

| 2 | Position Indicator | ABS | 1 | 16 | Washer Adjust Screw | Stainless Steel 304 | 2 |

| 3 | Spring Clip | Stainless Steel 304 | 1 | 17 | N ut Adjust Screw | Stainless Steel 304 | 2 |

| 4 | Metal Washer | Stainless Steel 304 | 1 | 18 | Adjust Screw | Stainless Steel 304 | 2 |

| 5 | OeWr asher | Engineering Plastic | 1 | 19 | Piston | Die Cast Aluminum Alloy | 2 |

| 6 | Body | Extruded Aluminum Alloy | 1 | 20 | Piston B earing | Engineering Plastic/Anodized | 2 |

| 7 | Inner Washer | Engineering Plastic/Hard Anodized | 1 | 21 | Bearing Piston | Engineering Plastic | 2 |

| 8 | Travel Stop | AlloySteel | 1 | 22 | O-ring Piston | N B R (VITON or EPDM on reuest) | 2 |

| 9 | O-ring Pinoin Top | N B R (VITON or EPDM on reuest) | 1 | 23 | Spring Group | Spring Steel | 0~12 |

| 10 | Bearing Pinoin Top | Engineering Plastic | 1 | 24 | O-ring End Cap | N B R (VITON or EPDM on reuest) | 2 |

| 11 | Pinion | AlloySteel (Electroless Nickel Plated) /SS304 is Optional | 1 | 25 | End Cap | Cast Aluminum/Polyester Paint | 2 |

| 12 | Bearing | Engineering Plastic | 1 | 26 | Cap Screw | Stainless Steel 304 | 8 |

| 13 | Bearing Pinoin bottom | N B R (VITON or EPDM on reuest) | 1 | 27 | Stop Screw | Stainless Steel 304 | 2 |

| 14 | Hole Sealant | N B R (VITON or EPDM on reuest) | 2 | 28 | Star Adaptor | Carobon Steel | 1 |

| Model | DA Weight (Kgs) |

SR Weight (Kgs) |

Air Volume opening | Air Volume closing | Model | DA Weight (Kgs) |

SR Weight (Kgs) |

Air Volume opening | Air Volume closing | Model | DA Weight (Kgs) |

SR Weight (Kgs) |

Air Volume opening | Air Volume closing |

| DA/SR 032 | 0.7 | - | 0.04 | 0.05 | DA/SR 092 | 4.6 | 5.2 | 0.64 | 0.473 | DA/SR 210 | 47 | 55 | 7.5 | 7.5 |

| DA/SR 040 | 1 | 1.1 | 0.08 | 0.11 | DA/SR 105 | 6.8 | 6.9 | 0.95 | 0.88 | DA/SR 240 | 67 | 80 | 11 | 9 |

| DA/SR 052 | 1.4 | 1.5 | 0.12 | 0.16 | DA/SR 125 | 8.9 | 10.1 | 1.6 | 1.4 | DA/SR 270 | 97 | 118 | 17 | 14 |

| DA/SR 063 | 2 | 2.1 | 0.21 | 0.23 | DA/SR 140 | 13 | 15 | 2.5 | 2.2 | DA/SR 300 | 110 | 130 | 23.8 | 29.7 |

| DA/SR 063 | 2.7 | 2.9 | 0.3 | 0.34 | DA/SR 063 | 20 | 24 | 3.7 | 3.2 | DA/SR 350 | 186 | 234 | 35.1 | 46.3 |

| DA/SR 083 | 3.1 | 3.6 | 0.43 | 0.47 | DA/SR 190 | 31 | 35 | 5.9 | 5.4 | DA/SR 400 | 289 | 360 | 52.6 | 56 |

| Model | DA Weight (Kgs) | SR Weight (Kgs) | Air volume opening | Air volume closing | Model | DA Weight (Kgs) | SR Weight (Kgs) | Air volume opening | Air volume closing | |

| 32 | 0.7 | - | 0.04 | 0.05 | 140 | 13 | 15 | 2.5 | 2.2 | |

| 40 | 1 | 1.1 | 0.08 | 0.11 | 160 | 20 | 24 | 3.7 | 3.2 | |

| 52 | 1.4 | 1.5 | 0.12 | 0.16 | 190 | 31 | 35 | 5.9 | 5.4 | |

| 63 | 2 | 2.1 | 0.21 | 0.23 | 210 | 47 | 55 | 7.5 | 7.5 | |

| 75 | 2.7 | 2.9 | 0.3 | 0.34 | 240 | 67 | 80 | 11 | 9 | |

| 83 | 3.1 | 3.6 | 0.43 | 0.47 | 270 | 97 | 118 | 17 | 14 | |

| 92 | 4.6 | 5.2 | 0.64 | 0.473 | 300 | 110 | 130 | 23.8 | 29.7 | |

| 105 | 6.8 | 6.9 | 0.95 | 0.88 | 350 | 186 | 234 | 35.1 | 46.3 | |

| 125 | 8.9 | 10.1 | 1.6 | 1.4 | 400 | 289 | 360 | 52.6 | 56 |

2026

/

Choosing a pneumatic angle seat valve shouldn't feel like a guessing game. ...

2026

/

With 15 years of expertise in manufacturing and global trade, Hearken deliv...

2026

/

In 2026, the U.S. solenoid valve market is defined by Smart Manufacturing a...

2026

/

Choosing the right valve is vital for system efficiency. A wrong choice can...

GET A QUOTE