How to Select the Right Pneumatic Angle Seat Valve: A Comprehensive Buyer’s Guide

Choosing a pneumatic angle seat valve shouldn't feel like a guessing game. ...

HUSR series spring return electric actuator is designed for fail-safe positioning of valves or dampers upon loss of supply voltage .Mechanical spring return design is used to position controlled devices to either fully open or fully closed positions without any external power source.

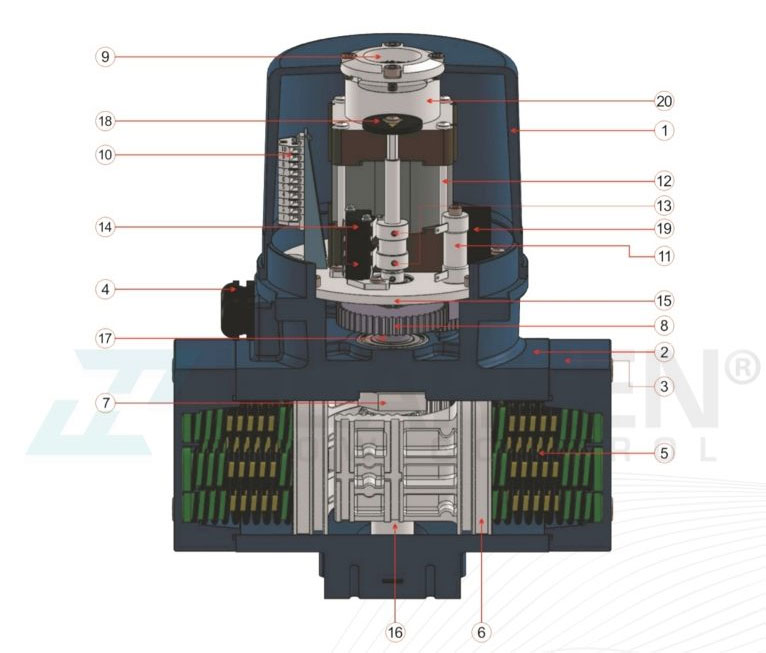

| 1.Product Construction Compact and designed for small spaces. |

|

4.Secure Operation Under critical conditions, this product provides excellent guarantee stability with mechanical solutions. Spring return electric actuator generates the required torque through energy storage mechanism for returning to safe position with no assistance during the spring return operation process. |

| 2.Low Maintenance Durable hassle-free operation. Spring effectively drives a 90°full stroke. Emergency on/off model employs a mechanical buffer without impacting pipes. |

5.Position Detection Stroke control switch with quick set up and reliability. Three dimensional indicator can be monitored in multi angles. Optional with switching value and analog quantity control. |

|

| 3.Secure And Stable Spring return electric actuator complies with SIL2/SIL3 standard regulations and is maintenance-free with anti-explosion applications. |

6.Adaptive Connection Parts Actuator flange and drive sleeves comply with ISO5211 standards. A versatile design that offers its replacement. |

| NO. | Part Name | Material | NO. | Part Name | Material |

| 1 | Upper Cap | ADC12 | 11 | Space Heater | Ceramic |

| 2 | Body | AL104 | 12 | Electrical Motor | Integrated Set |

| 3 | Side Cap | ADC12 | 13 | Adjustment Cam | ADC12 |

| 4 | Connection Lock | Nylon | 14 | Microswitch | Integrated Assembly |

| 5 | Safety Spring | Spring Steel | 15 | Mounting Retaining Plate | Q235 |

| 6 | Piston | ADC12 | 16 | Output Shaft | 45# Steel |

| 7 | Spacing Block | 45# steel | 17 | Locating Bearing | Bearig Steel |

| 8 | Driving Gear | 40CR | 18 | Position Indicator | Nylon |

| 9 | Display Window | Tempered Glass | 19 | Capacitor | Composite Material |

| 10 | Wiring Terminal | Flame-retarded Nylon | 20 | Brake | Integrated Set |

|

Model |

Torque (Nm) |

Torque (In.lbs) |

Spring Torque at 90°(Nm) |

Spring Torque at 0°(Nm) |

Electrical Torque at 90°(Nm) |

Electrical Torque at 0°(Nm) |

Electric Current (DC24V) |

Electric Current (AC110V) |

|

HUSR1 |

20 |

177 |

31.4 |

20 |

75 |

75 |

1.8A |

0.9A |

|

HUSR2 |

38 |

336 |

62.5 |

38 |

110 |

110 |

2.5A |

1.2A |

|

HUSR3 |

55 |

487 |

92 |

55 |

180 |

180 |

3.5A |

1.6A |

|

HUSR3 |

70 |

620 |

110 |

70 |

220 |

220 |

5A |

1.8A |

|

HUSR4 |

140 |

1239 |

220.2 |

140 |

400 |

400 |

8.5A |

4.2A |

|

HUSR4 |

210 |

1859 |

293.6 |

210 |

600 |

600 |

9.5A |

4.5A |

|

HUSR5 |

300 |

2655 |

527 |

300 |

920 |

920 |

21A |

5.5A |

|

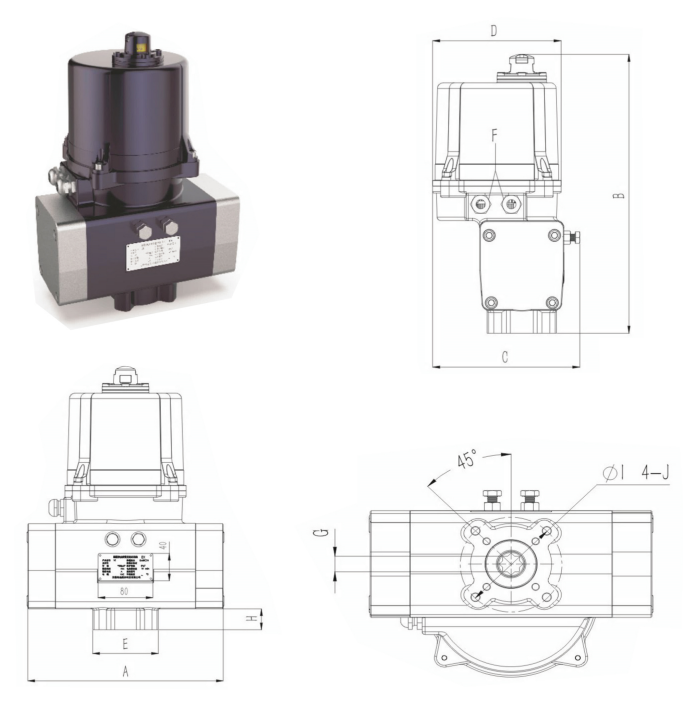

Model |

A |

B |

C |

D |

E |

F |

G |

H |

øI |

J |

|

HUSR1 |

189 |

230 |

125 |

118 |

75 |

M20*1.5 |

14 |

16 |

F03 |

M5 |

|

HUSR2 |

229 |

303 |

162 |

145 |

75 |

M20*1.5 |

14 |

17 |

F05/F07 |

M6/M8 |

|

HUSR3 |

266 |

380 |

199 |

177 |

96 |

M20*1.5 |

17 |

19 |

F07/F10 |

M8/M10 |

|

HUSR4 |

377 |

436 |

240 |

206 |

120 |

M20*1.5 |

22 |

25 |

F10 |

M10 |

|

HUSR5 |

406 |

535 |

280 |

260 |

120 |

M20*1.5 |

27 |

30 |

F10/F12 |

M10/M12 |

|

Model |

HUSR1 |

HUSR2 |

HUSR3 |

HUSR3 |

HUSR4 |

HUSR4 |

HUSR5 |

|

Torque |

177in.Lbs 20Nm |

336in.Lbs 38Nm |

487in.Lbs 55Nm |

620in.Lbs 70Nm |

1239in.Lbs 140Nm |

1859in.Lbs 210Nm |

2655in.Lbs 300Nm |

|

Power(W) |

10 |

18 |

40 |

60 |

90 |

120 |

200 |

|

Voltage(DC/AC) |

120VAC/220VAC、24VDC |

||||||

|

Frequency(Hz) |

50/60 |

||||||

|

Operation Mode |

S2-20Min |

||||||

|

Start Time(S) |

12 |

8 |

8 |

8 |

10 |

12 |

12 |

|

Spring Return Time(S) |

5 |

3 |

3 |

3 |

5 |

5 |

5 |

|

Spring Circle Life(Times) |

100000 |

100000 |

100000 |

100000 |

100000 |

100000 |

100000 |

|

Ambient Temperature |

-25℃~65℃ |

||||||

|

Ambient Humidity(25℃) |

95% |

||||||

|

Protection Class |

NEMA4X & IP67 |

||||||

|

Manual Override |

Optional with open, need to be customized |

||||||

|

Manual Override Method |

Operation under power off (system power supply interrupted) |

||||||

|

Power Loss Return Direction |

Close (or open) |

||||||

|

Half Stop |

Electromagnetic brake control |

||||||

|

Cable Entry |

2M201.5 |

||||||

|

Lubrication |

Grease |

||||||

|

Limit Method |

Electronic control:electronic limit Spring return at power failure:mechanical limit |

||||||

|

On-Off Type Signal |

Passive feedback,two-wire/three-wire |

||||||

|

Mechanical Stopper |

Full close/open machanical stopper |

||||||

2026

/

Choosing a pneumatic angle seat valve shouldn't feel like a guessing game. ...

2026

/

With 15 years of expertise in manufacturing and global trade, Hearken deliv...

2026

/

In 2026, the U.S. solenoid valve market is defined by Smart Manufacturing a...

2026

/

Choosing the right valve is vital for system efficiency. A wrong choice can...

GET A QUOTE