The Brief Induction on 3-Way Valve Applications

Are you struggling with inefficient fluid control in your system? Ignoring this can lead to system failures, costly downtime, and wasted resources. A 3-way valve is the crucial component you need to manage fluid flow, mixing, or diversion with precision, ensuring optimal system performance.

A 3-way valve is an essential fluid control device that features three ports and an internal mechanism, such as a ball or plug, allowing it to mix two fluids, divert a single fluid into two different paths, or select between two incoming fluid sources. These valves are indispensable across various industries for regulating temperature, automating processes, and enhancing system reliability.

To truly master fluid control, let’s explore the profound and diverse applications of these robust components in detail.

Basic Knowledge and Working Principle of Three-Way Valves

A three-way valve is a mechanical device designed to control fluid flow, offering greater operational flexibility than a standard on/off valve. Its core principle relies on the movement of an internal element, typically a rotating ball. This element aligns the three ports—which can be configured as one inlet and two outlets, or two inlets and one outlet—to achieve specific actions. For instance, in mixing, two streams are combined into one. In diversion, a single stream is directed to one of two paths. Recognizing this simple yet powerful mechanism is the first step in successful fluid management.

Three-Way Valve Applications Across Industries

Industrial Applications

Three-way valves are vital for ensuring stable and efficient continuous processes in heavy industry.

-

Chemical Production: They are crucial for precise material mixing, diversion, and switching of chemicals. By accurately managing flow ratios and sequencing, these valves help ensure process stability, preventing inconsistent reactions and maintaining product quality in high-stakes chemical manufacturing environments.

-

Oil and Natural Gas: These valves are indispensable for controlling flow direction within pipeline networks. They efficiently route oil, gas, or refined products to different storage or processing facilities, helping to optimize pipeline transportation by quickly switching flow paths and maximizing throughput.

-

Power Industry: In power generation, 3-way valves are used to regulate water flow in cooling systems for critical equipment like turbines. This precise control helps maintain equipment temperature within safe limits, preventing dangerous overheating and ensuring the efficiency and longevity of the plant.

Daily Life Applications

The benefits of 3-way valves contribute directly to your daily comfort and convenience.

|

Application |

Function |

Benefit |

|

Home Heating |

Regulate the flow direction of hot water or steam to different zones. |

Achieves precise temperature control and energy efficiency in separate rooms or floors. |

|

Kitchen and Bathroom |

Mix hot and cold water streams at the point of use. |

Provides comfortable, consistent water temperature instantly, enhancing comfort and safety. |

|

Irrigation System |

Distribute water sources to different planting areas or zones. |

Ensures uniform and efficient irrigation across the landscape, conserving water and promoting plant health. |

Medical Applications

In the medical field, 3-way valves provide the precision necessary for critical patient care.

-

Infusion Equipment: They allow for the precise control of drug mixing and infusion sequences. This is essential for safe patient care, ensuring accurate delivery of multiple medications and fluids at the correct dosage and rate.

-

Medical Equipment: Valves are used to guide the flow of liquid between different components in sophisticated devices, such as dialysis equipment. They manage blood and dialysate flow, supporting the vital filtering process while meeting stringent safety standards.

Other Essential Applications

The utility of these valves extends into specialized mechanical and marine systems:

-

Automobile Manufacturing: They are key to fluid control in engine cooling and air conditioning systems, managing the flow of coolant or refrigerant to maintain optimal operating temperatures and cabin comfort.

-

Ship Industry: Valves are used to control the flow direction of bilge water and ballast water. This is fundamental for maintaining the ship's stability, balance, and safe trim during loading, unloading, and sailing operations.

Correct Use and Maintenance Points

To ensure your 3-way valve operates efficiently and lasts for years, focus on these critical steps.

Selection Points

You must choose the correct valve based on the fluid type (corrosive, temperature, pressure) and the required function (mixing or diverting). The valve's material (e.g., stainless steel, brass) and pressure rating must match your system’s specifications. Selecting the correct size is equally important to avoid pressure drops. Always consult the manufacturer’s flow characteristics to ensure the valve performs as expected in your specific application.

Installation Specifications

Always install your valve following the flow direction indicated on the body. Ensure all connections are secure and leak-free using appropriate sealing materials. The piping near the valve must be properly supported to prevent mechanical stress on the valve body. Correct installation minimizes the risk of early failure and guarantees the valve can operate smoothly and effectively throughout its service life.

Maintenance

Routine maintenance prevents unexpected shutdowns. Check regularly for any signs of leaks or unusual operation noise. For automated valves, confirm the actuator is calibrated and responding accurately to the control signals. Periodically operating the valve through its full range of motion helps prevent internal parts from seizing or sticking. A consistent maintenance schedule will significantly extend the valve's working life.

Summary

Three-way valves are versatile and essential tools for precise fluid control, handling mixing, diverting, and selection across countless applications. Optimal performance hinges on correct selection, installation, and regular maintenance. For reliable fluid control solutions, contact the experts at Hearken via info@hearkenflow.com.

Frequently Asked Questions (FAQ)

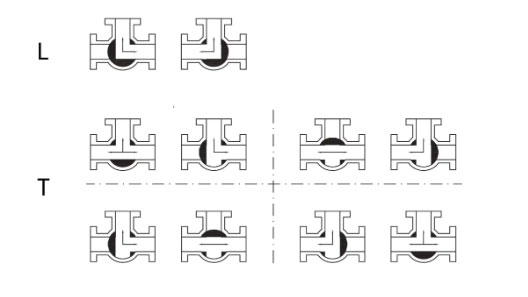

1. What is the main difference between an L-port and a T-port 3-way valve?

Answer: The difference lies in the bore configuration inside the ball. An L-port valve allows flow either straight through or at a 90-degree angle, making it ideal for diverting flow or selecting one of two sources. A T-port valve can also divert or select, but it can additionally connect all three ports simultaneously in one position, which is useful for certain flow combining or transfer operations.

2. Can a 3-way valve be used as a simple shut-off valve?

Answer: Yes, a 3-way valve can effectively act as a shut-off valve, but only for one flow path at a time. In its diverting function, when flow is directed to one outlet, the other outlet path is effectively shut off. Similarly, in a mixing configuration, you can stop the flow from one inlet while allowing the other to pass through.

3. How do I determine if I need a 3-way mixing valve or a diverting valve?

Answer: You need a mixing valve if your goal is to combine two separate input streams (e.g., hot and cold water) into a single output stream with a controlled temperature or composition. You need a diverting valve if your goal is to take a single input stream and send it to one of two possible output destinations (e.g., routing water to one of two different zones).

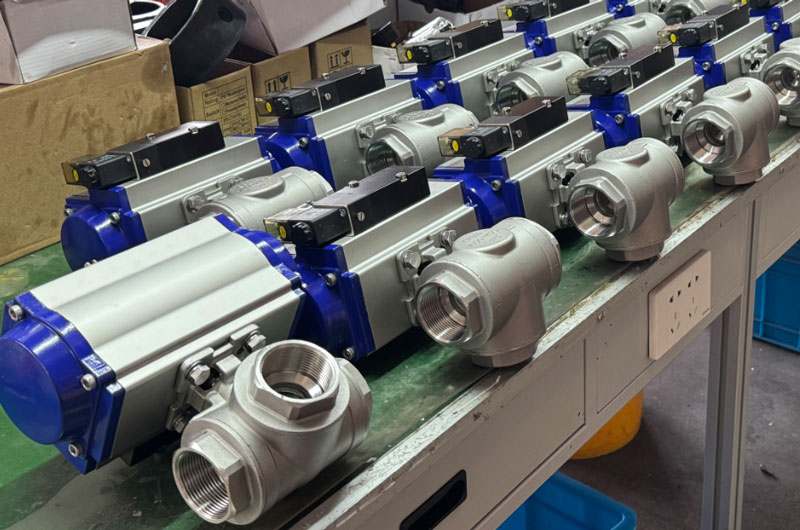

4. Are 3-way valves typically manually operated or automated?

Answer: They can be either. Manually operated 3-way valves require human intervention to turn a handle or lever to change the flow path. Automated 3-way valves use an actuator (electric or pneumatic) to change the flow path automatically based on a control signal from a thermostat or other control system, which is common in industrial and HVAC applications.

5. What maintenance is required for a 3-way valve?

Answer: Key maintenance tasks include regular visual inspections for leaks, ensuring the actuator (if present) is calibrated and functioning correctly, and periodically cycling the valve through its full range of motion. This prevents internal components from seizing, especially in systems where the valve remains in one position for long periods.