Solenoid Valve vs. Electric Valve: A Comprehensive Comparison Guide

Choosing the right valve is vital for system efficiency. A wrong choice can...

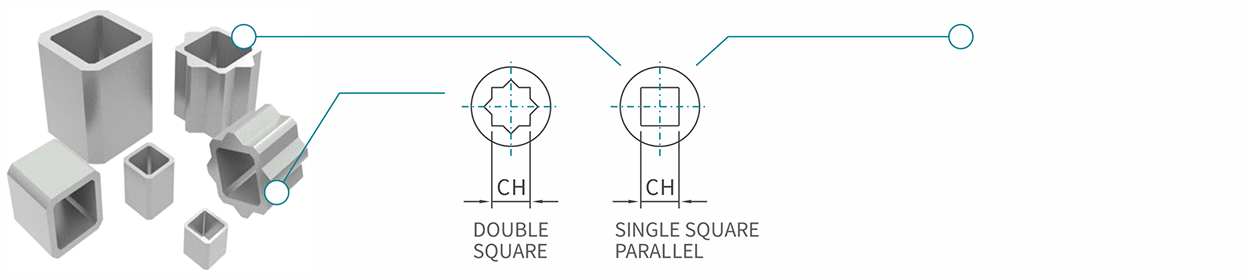

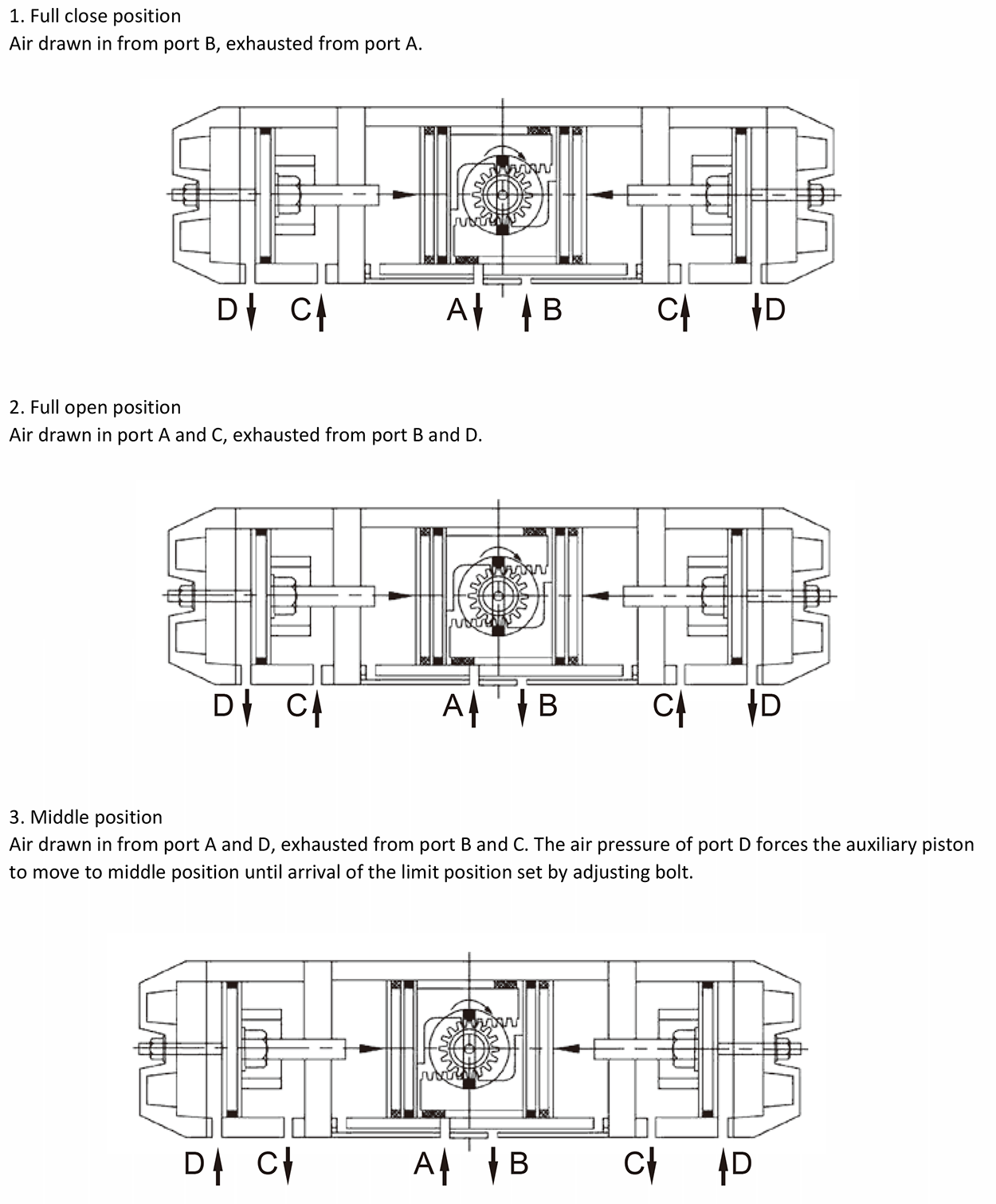

Three Position Design Pneumatic Actuator is a special type of actuator, which can provide three-position operation modes of 0°, 45°, 90°, and 180°. The intermediate position is achieved by the mechanical brake produced by the movement of the two auxiliary pistons. The intermediate position is adjustable. For example, the actuator with 90° stroke can provide intermediate positions of 20°, 30°, 50°, 70° and so on.

■ Travel adjustment:±5°for the rotation at 0°and 90°

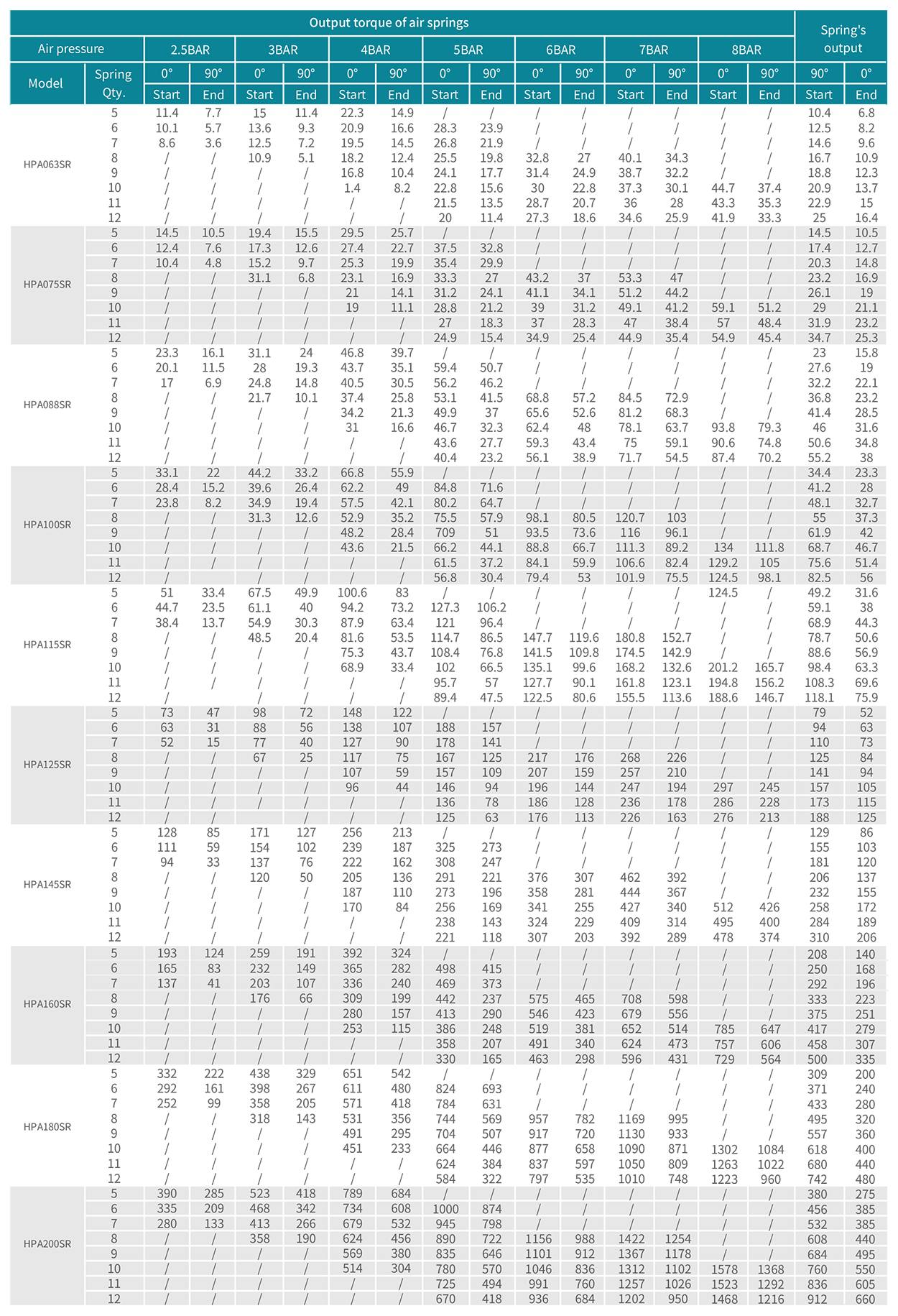

■ Torque Range:Double acting: From 20Nm@5bar to 1923Nm@5bar

Spring return: From 8.5Nm@5bar to 827Nm@5bar

■ Application:Indoor or outdoor

■ Operating media:Dry or lubricated air, or the non-corrosive gases.

■ Air supply pressure:Working pressure:2-8 Bar

The maximum particle diameter must less than 30um

Maximum supply: 10 Bar

Standard Temperature:-20~+80 Degree

Low Temperatur -40~+80Degree

High Temperature: -15~+150 Dgree

All actuators manufactured by HEARKEN are individually tested, Testing is carried out to check the leakage in both internal and external,The angle of rotation and Torque valuesAll bodies are stamped with year,month of production.,size and serial number.

|

|

|

|

|

|

| Solenoid Valve | Limit Switch Boxes | Electro-pneumatic Positioner | Declutjable Manual Override Gearbox | Hign Visibility Indicator |

|

|

|

|

|

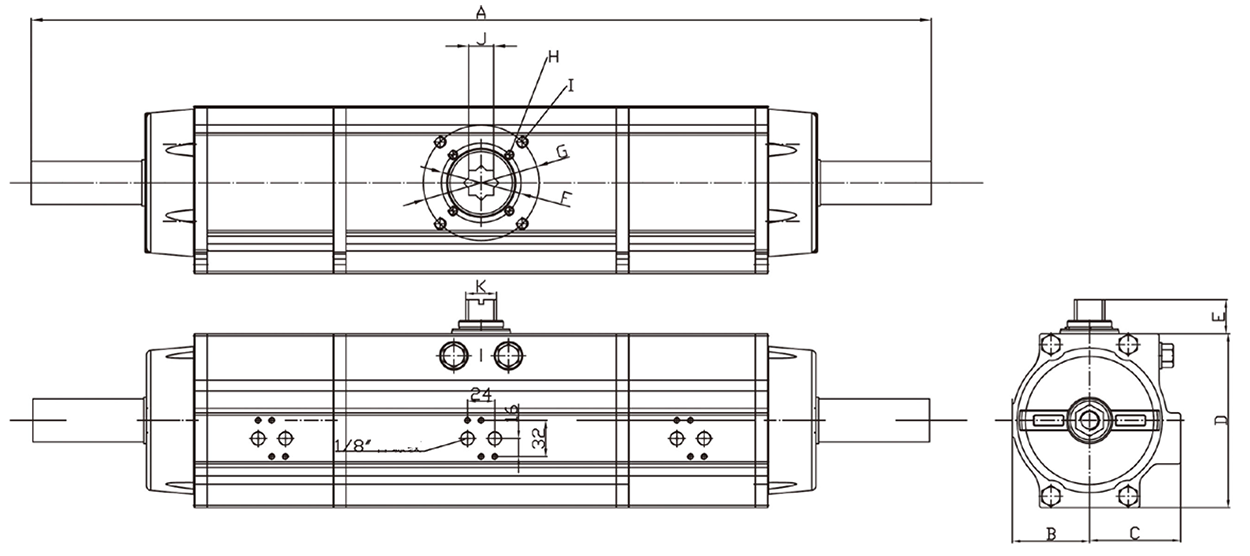

Drive and Flange to ISO5211 |

The NAMUR Drive Pinion and |

Air supply connection is designed |

| No. | Part Name | Material | Protection | Qty | No. | Part Name | Material | Protection | Qty | |

| 1 | Body | Alu Extrusion | Anodising | 1 | 21 | Cam | Alloy Steel | Galvanizing | 1 | |

| 2 | Pinion | Alloy Steel | ENP Coating | 1 | 22 | Inner Washer | Engineered | 1 | ||

| 3 | Piston | Die Cast Alu | Cr+3 Coating | 2 | Plastics | |||||

| 4 | Body Mid Part | Aluminum | Polyester Coating | 2 | 23 | Washer | Engineered | 1 | ||

| 5 | Body Ext. Part | Alu Extrusion | Anodising | 2 | Plastics | |||||

| 6 | Cap | Die Cast Alu | Cr+3 & Polyester | 2 | 24 | Metal Washer | Stainless Steel | 1 | ||

| 7 | Piston | Die Cast Alu | Cr+3 Coating | 2 | 25 | Circlip | Stainless Steel | 1 | ||

| 8 | Piston Shaft | Stainless Steel | 2 | 26 | Indicator Body | Plastic | 1 | |||

| 9 | Nut | Stainless Steel | 2 | 27 | Indicator Part | Plastic | 4 | |||

| 10 | Lower Stem | Engineered | 1 | 28 | Indicator Screw | Alloy Steel | Galvanizing | 1 | ||

| Bushing | Plastics | 29 | Adjustment Screw | NBR | 2 | |||||

| 11 | Lower Stem | NBR | 1 | O-Ring | ||||||

| O-Ring | 30 | Adjustment Screw | Stainless Steel | 2 | ||||||

| 12 | Upper Stem | Engineered | 1 | Washer | ||||||

| Bushing | Plastics | 31 | Nut | Stainless Steel | 2 | |||||

| 13 | Upper Stem | NBR | 1 | 32 | Hexagon Bolt | Stainless Steel | 2 | |||

| O-Ring | 33 | Outer Nut | Stainless Steel | 2 | ||||||

| 14 | Slide Guide | Engineered | 4 | 34 | Cap Bolt | Stainless Steel | 8 | |||

| Plastics | 35 | O-Ring | NBR | 4 | ||||||

| 15 | Piston O-Ring | NBR | 4 | 36 | Washer | Stainless Steel | 8 | |||

| 16 | Piston Shaft | NBR | 2 | 37 | Bolt | Stainless Steel | 4 | |||

| O-Ring | 38 | Nut | Stainless Steel | 8 | ||||||

| 17 | Body O-Ring | NBR | 4 | 39 | Cap | Die Cast Alu | Cr+3 & Polyester | 2 | ||

| 18 | Cap O-Ring | NBR | 2 | 40 | Sealant | NBR | 1 | |||

| 19 | Piston Shaft | NBR | 2 | 41 | Slide Piston | Engineered Plastics | 1 | |||

| O-Ring | ||||||||||

| 20 | Shaft Cap | NBR | 2 | |||||||

| O-Ring |

|

Model |

Air Supply Pressure(Unit:bar) | |||||||||

| 2 | 2.5 | 3 | 4 | 4.5 | 5 | 5.5 | 6 | 7 | 8 | |

| HPA063 | 15 | 18 | 22 | 29 | 33 | 36 | 40 | 44 | 51 | 58 |

| HPA075 | 20 | 25 | 30 | 40 | 45 | 50 | 55 | 60 | 70 | 80 |

| HPA088 | 31 | 39 | 47 | 63 | 70 | 78 | 86 | 94 | 110 | 125 |

| HPA100 | 45 | 56 | 68 | 90 | 102 | 113 | 124 | 135 | 158 | 181 |

| HPA115 | 66 | 83 | 99 | 132 | 149 | 165 | 182 | 198 | 231 | 264 |

| HPA125 | 100 | 125 | 150 | 200 | 226 | 251 | 276 | 301 | 351 | 401 |

| HPA145 | 171 | 214 | 256 | 342 | 385 | 427 | 470 | 513 | 598 | 684 |

| HPA160 | 266 | 332 | 399 | 532 | 598 | 665 | 731 | 798 | 931 | 1064 |

| HPA180 | 426 | 532 | 638 | 851 | 958 | 1064 | 1170 | 1277 | 1490 | 1702 |

| HPA200 | 426 | 532 | 638 | 851 | 958 | 1064 | 1170 | 1277 | 1490 | 1702 |

| Model | ISO5211 | A | B | C | D | E | F | G | H | I | J | K |

| HPA063 | F05/F07 | 378 | 36 | 45 | 81 | 20 | 50 | 70 | M6*8 | M8*12 | 14 | 11 |

| HPA075 | F05/F07 | 468 | 42 | 45 | 97 | 20 | 50 | 70 | M6*8 | M8*12 | 17 | 17 |

| HPA088 | F05/F07 | 537 | 48 | 59 | 109 | 20 | 50 | 70 | M6*8 | M8*12 | 17 | 17 |

| HPA100 | F07/F10 | 566 | 55 | 68 | 121.5 | 20 | 70 | 102 | M8*8 | M10*14 | 17 | 17 |

| HPA115 | F07/F10 | 731 | 64 | 73 | 142 | 30 | 70 | 102 | M8*12 | M10*14 | 22 | 27 |

| HPA125 | F07/F10 | 791 | 68 | 80 | 153.5 | 30 | 70 | 102 | M8*12 | M10*14 | 22 | 27 |

| HPA145 | F10/F12 | 898 | 78.5 | 90 | 179 | 30 | 102 | 125 | M10*15 | M12*18 | 27 | 27 |

| HPA160 | F10/12 | 986 | 98 | 100 | 192 | 30 | 102 | 125 | M10*15 | M12*18 | 27 | 27 |

| HPA180 | F14 | 1050 | 102 | 102 | 222 | 30 | / | 140 | / | M16*25 | 36 | 36 |

| HPA200 | F14 | 1101 | 112 | 112 | 244 | 30 | / | 140 | / | M16*25 | 36 | 36 |

2026

/

Choosing the right valve is vital for system efficiency. A wrong choice can...

2026

/

A solenoid valve is an electromechanical switch used to control fluid or ga...

2026

/

The landscape of fluid control is changing fast. In the era of the Industri...

2026

/

If you need reliable and compact fluid control, you have probably realized ...

GET A QUOTE