Top Manufacturers of Pneumatic Positioners in the United States

The United States industrial landscape relies heavily on pneumatic positioners to ensure precision in valve automation. The market is structured into three distinct categories: domestic global giants, specialized niche manufacturers, and international players with a strategic presence in North America.

Tier 1: Global Market Leaders (Headquartered in USA)

These corporations represent the pinnacle of valve instrumentation, setting global standards for "smart" digital integration and long-term reliability.

-

Emerson Electric Co. (Fisher™ / FIELDVUE™)

-

Headquarters: St. Louis, Missouri.

-

Core Strength: Emerson’s Fisher FIELDVUE series is the undisputed gold standard. They pioneered the transition from simple analog positioners to Digital Valve Controllers (DVC).

-

Key Features: Renowned for Performance Diagnostics (PD) and Advanced Diagnostics (AD), allowing plants to move toward predictive maintenance. They are the primary choice for critical infrastructure in nuclear power, refining, and aerospace.

-

-

Flowserve Corporation (Valtek / PMV / Logix)

-

Headquarters: Irving, Texas.

-

Core Strength: Flowserve provides high-performance solutions for severe service conditions through its Logix (smart) and PMV (rugged analog) brands.

-

Key Features: Known for extreme durability against vibration and corrosion. Their "one-button" quick-calibration technology is highly favored by field technicians for its ease of use in harsh environments.

-

-

Baker Hughes (Masoneilan™)

-

Headquarters: Houston, Texas.

-

Core Strength: Masoneilan is a cornerstone of American engineering, specializing in high-precision control for the energy sector.

-

Key Features: Their SVI (Smart Valve Interface) series offers industry-leading flow capacity and responsiveness. These units are engineered to withstand the extreme pressures and temperatures typical of midstream and upstream oil and gas operations.

-

Specialized & Niche US Manufacturers

These companies focus on specific technology segments or "Made in USA" excellence for targeted industrial needs.

-

ControlAir Inc.

-

Headquarters: Amherst, New Hampshire.

-

Core Strength: A specialist in precision air pressure regulation and high-repeatability transducers.

-

Key Features: ControlAir positioners are prized for their compact footprints and exceptionally low hysteresis. They are frequently used in medical devices, laboratory automation, and food processing.

-

-

VRC (Valve Related Controls)

-

Headquarters: Houston, Texas.

-

Core Strength: A dedicated manufacturer focusing on rugged, modular pneumatic and electro-pneumatic positioners.

-

Key Features: VRC units are built for simplicity and field-repairability. Their modular design allows for easy upgrades to explosion-proof or water-tight ratings, making them a favorite in the pulp, paper, and fertilizer industries.

-

-

Bray International, Inc.

-

Headquarters: Houston, Texas.

-

Core Strength: A global flow control leader providing integrated valve and automation packages.

-

Key Features: Their positioners are specifically optimized for rotary valves (butterfly and ball valves). They provide a cost-effective balance of performance and ease of integration for water treatment and HVAC systems.

-

Key Global Players with Major US Operations

These manufacturers utilize extensive U.S. distribution, regional support, and compliance with North American standards to serve the domestic market.

-

SMC Corporation of America (Noblesville, Indiana)

-

ABB Measurement & Analytics (Warminster, Pennsylvania)

-

Siemens Industry, Inc. (Alpharetta, Georgia)

-

Hearken (Hearken Flow)

-

Market Positioning: Hearken has emerged as a high-agility challenger by bridging the gap between traditional mechanical reliability and modern digital intelligence. In the U.S. market, rather than maintaining localized customization centers, Hearken operates through a Global Supply and Strategic Partnership model, ensuring their high-performance hardware is readily available through specialized industrial distributors and value-added resellers.

-

Interoperability & Standards: Hearken positioners are engineered with a "Drop-in Replacement" philosophy. They adhere strictly to NAMUR and ANSI/ISA mounting standards and utilize NPT air connections, allowing U.S. engineers to install them onto existing domestic actuators (like Bettis or Jamesbury) without specialized brackets or adapters.

-

Technical Edge – "Sensitivity & Stability": The brand's core identity revolves around its high-sensitivity pilot valve technology. Their positioners are designed to detect micro-fluctuations in signal and pressure, ensuring ultra-stable stem positioning in high-cycle applications. This is critical for U.S. chemical and pharmaceutical industries where batch consistency is paramount.

-

Environmental Compliance: Aligning with U.S. EPA and ESG goals, Hearken focuses on "Low-Bleed" pneumatic designs. Their units minimize steady-state air consumption, significantly reducing the energy costs and carbon footprints of large-scale pneumatic systems in shale gas and utility plants.

-

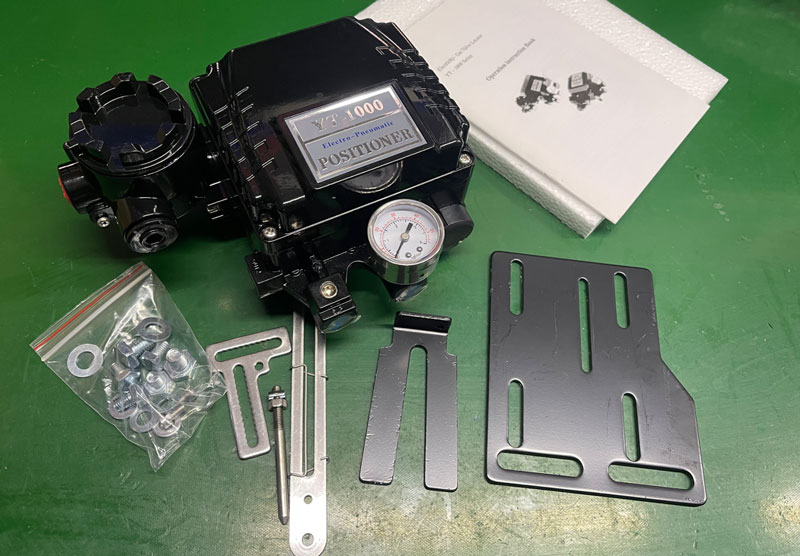

Digital Accessibility: Their "YT" and "ALP" series offer intelligent auto-tuning algorithms. By simplifying complex calibration into a digital process, they help U.S. facilities overcome the "technical skills gap," allowing even general maintenance staff to commission valves with high precision.

-

Conclusion

The US market for pneumatic positioners is defined by a transition toward intelligence and efficiency. While legendary brands like Fisher and Masoneilan continue to lead in large-scale critical infrastructure, agile players like Hearken are gaining ground by offering high-sensitivity, low-bleed alternatives that integrate seamlessly with existing American valve standards. For the US buyer, the choice depends on balancing advanced diagnostic needs with cost-effective, high-precision performance.

FAQ

1. What is the difference between a Pneumatic (P/P) and an Electro-Pneumatic (I/P) positioner?

A P/P positioner receives a pneumatic signal (usually 3-15 psi) to control the valve, whereas an I/P positioner receives an electrical current signal (usually 4-20 mA). Most modern US facilities are moving toward I/P or digital positioners for better integration with control systems (DCS).

2. Why is "Low-Bleed" technology important for US manufacturers?

Low-bleed designs minimize the continuous escape of compressed air when the valve is in a steady state. This reduces compressor energy costs and, in the case of natural gas systems, helps facilities comply with EPA regulations regarding methane emissions.

3. Can Hearken positioners be easily retrofitted onto existing US-made actuators?

Yes. Hearken designs its products to be "Actuator Agnostic." By adhering to NAMUR (for rotary) and standard linear mounting patterns, they can be installed on most common US actuators like those from Emerson, Flowserve, or Bray without requiring custom-manufactured mounting kits.

4. What certifications should I look for when buying positioners in the USA?

For hazardous environments, ensure the device carries FM (Factory Mutual) or CSA (Canadian Standards Association) certifications, which verify the device is explosion-proof or intrinsically safe according to North American safety codes.

5. How do "Smart" positioners like Fisher's FIELDVUE help with maintenance?

Smart positioners record data such as friction, valve travel, and air pressure. This allows engineers to use software to see if a valve is sticking or failing before it breaks, enabling "Predictive Maintenance" rather than waiting for a plant shutdown.